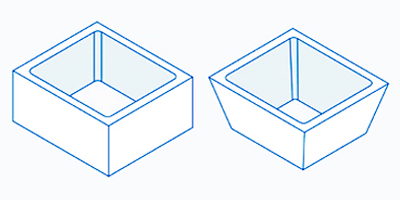

Design Tips for Clips

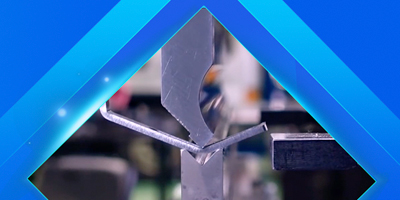

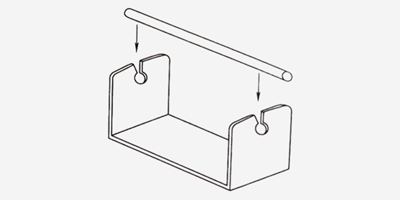

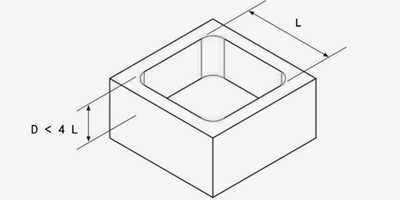

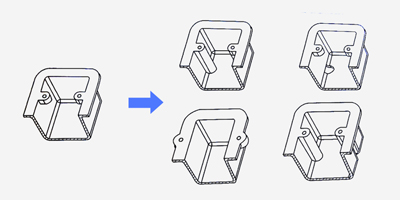

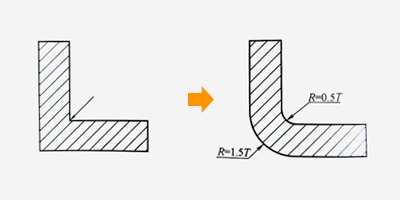

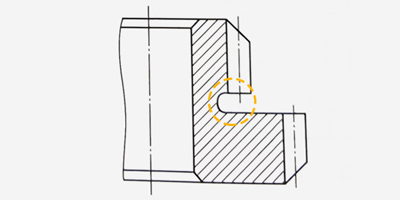

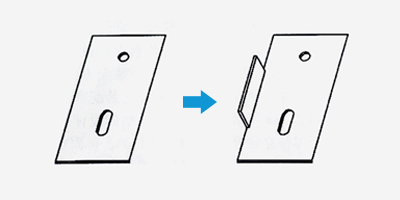

The client asked for design with no screws, so we chose clips. However, the clip hook was broken during drop testing, what should we do?

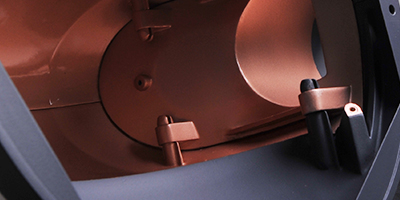

Learn how to design proper clips to ensure both the function and durability.