Steel vs. Aluminium vs. Carbon Fiber

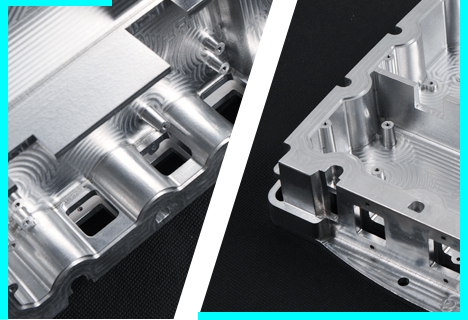

Steel is a traditional material that offers high strength and durability. However, steel is heavy and prone to corrosion, which can reduce the energy efficiency and lifespan of the battery. In addition, steel has high thermal conductivity, which affects the battery performance and safety. Aluminum, in contrast, is preferred due to its lightweight and high strength-to-weight ratio. It is also more resistant to corrosion than steel.

Sounds like aluminum wins in every way, no material is without its challenges, however. There is also the poor impact performance of metal materials. Carbon fiber reinforced polymer (CFRP), a newer and more innovative composite material, offers lightweight, anti-impact, durable and flexible performance. However, it is also more expansive. Moreover, its thermal expansion mismatch with the battery cells, which makes it still a cautious choice.