One of the common defects on plastic injection molded parts is sink mark, which appears as a dimple or shallow depression on the surface of a molded part and impacts the part quality and visual appearance.

As a manufacturing supplier, we suggest eliminating the sink mark on molded parts before it occurs, instead of looking for solutions in a rush when the sink mark appears. Looking for solutions means that the injection molded part design has to be modified, or engineers have to adjust the mold gates or runners. The measures mentioned not only increase the production cost but prolong the product development cycle. The worst thing is with all efforts have been made, you’ll have to make the compromise that sink marks are still there.

Here are topics about how to avoid sink marks on plastic injection molded parts from the beginning such as selecting proper materials, improving product design, etc. Hopefully, the part defects can be eliminated at the first place to further improve the product quality and increase production efficiency.

Original Design Sink marksCavity Optimal Design

The defects on molded parts and its improvement

Eliminate sink marks by using the proper materials

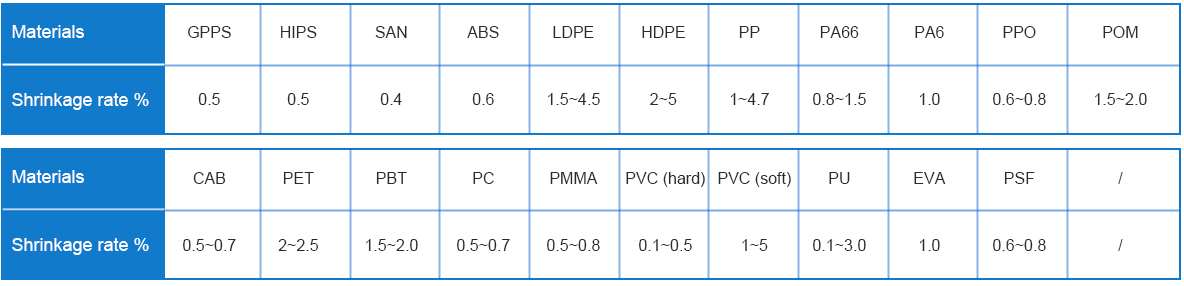

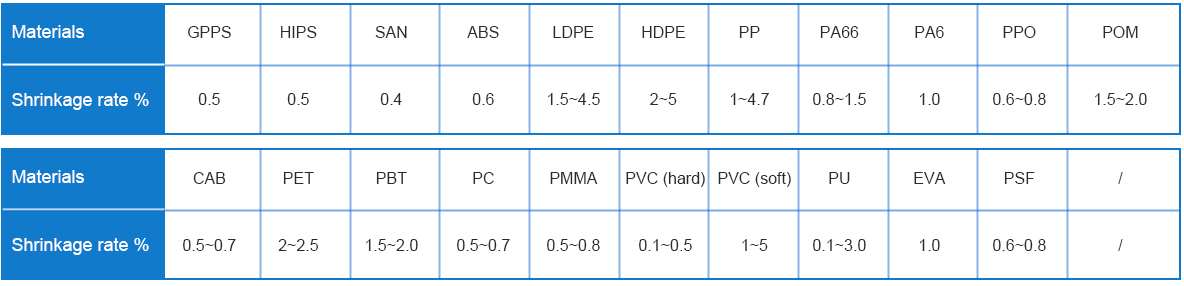

All resins shrink as they cool. The shrinkage rate of different plastic materials varies. The semi-crystalline plastics, such as PBT, PP, are susceptible to sink and easily causing sink marks on part surface. The amorphous plastics, such as PMMA, ABS, etc., are less prone to sink and can mitigate the shrinking risks. Comparing with non-reinforced thermoplastic and non-structure foam, the reinforced plastics and structure foam offers lower shrinkage rate and reduces the shrinking defects to some degree. See the below chart about shrinkage rate of different plastic materials.

In addition to that, the plastic materials with lower fluidity, such as PC, are prone to cause sink marks, because the melted materials cannot be well replenished when it cools and shrinks. But it doesn’t mean that you can do nothing but choosing the materials with lower shrinkage rate for your product, just for mitigating the shrinking risks on plastic parts. Many factors affect the materials selection, shrinking is only one of the considerations. Try to use the materials with lower shrinkage rate, only when other conditions meet the needs.

Avoid sink marks from the part design

1. The wall thickness should be thin rather than thick

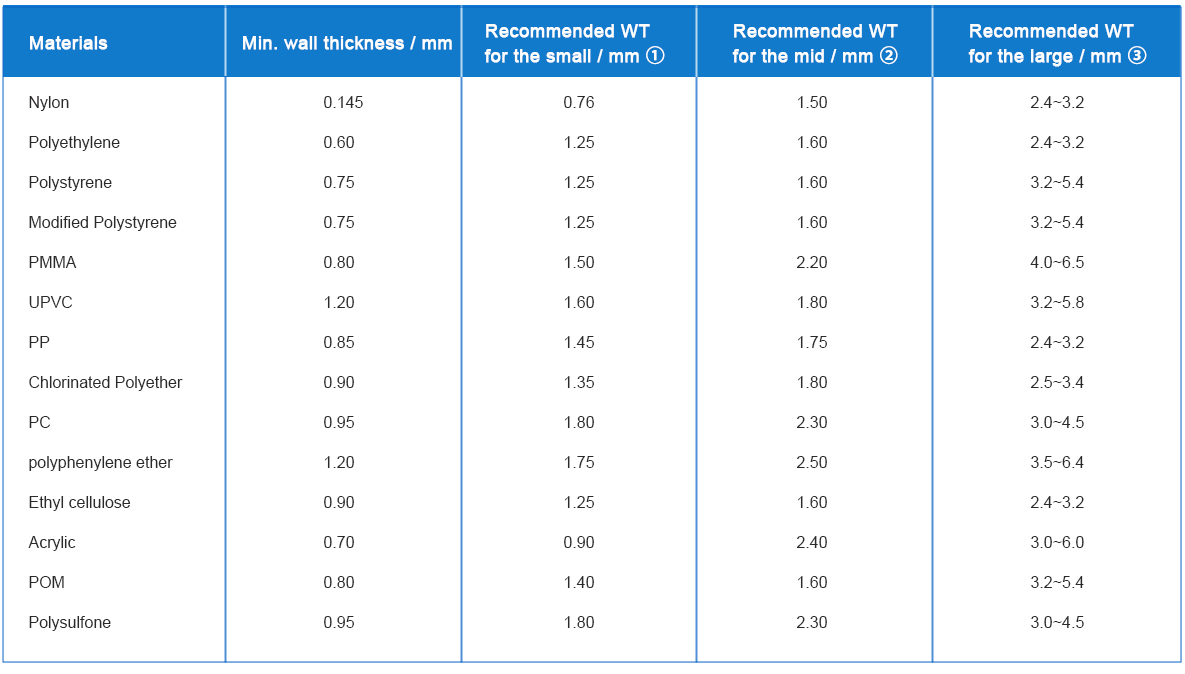

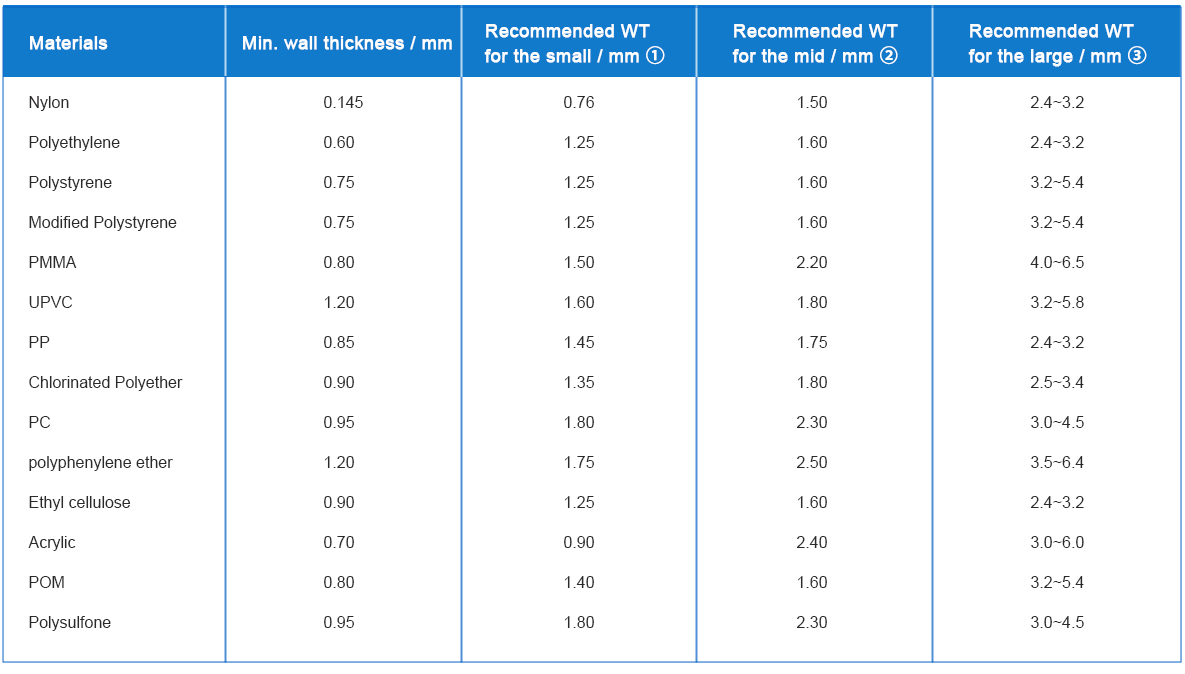

The shrinking degree of plastic molded parts are related to the wall thickness of part. The thick wall thickness can cause too much shrinking on plastic molded parts and are prone to generate sink marks. Certainly, the over thick wall thickness not only waste resources, but prolongs the injection molding cycle, further increasing the manufacturing cost. The below chart demonstrates the thinnest wall thickness and the recommended wall thickness of common materials.

① Recommended wall thickness for small-size molded parts ② Recommended wall thickness for mid-size molded parts

③ Recommended wall thickness for large-size molded parts

2. Ensure the uniform wall thickness

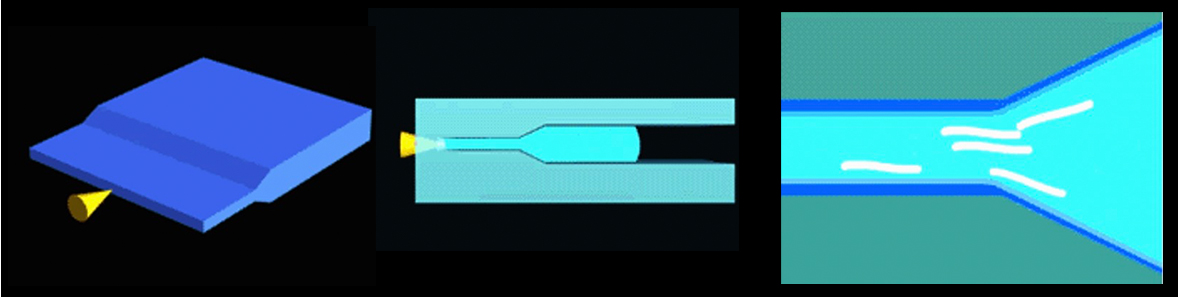

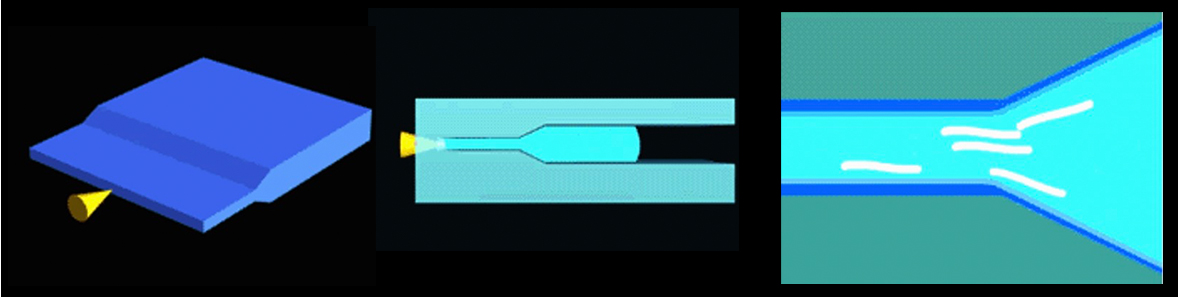

When injection molding the part with non-uniform wall thickness, the hot plastic flowing in thin wall thickness cools fast, while the hot plastic in the thick cools more slowly. The uneven cooling drives more shrinking and sink marks. Ensuring the uniform wall thickness is one of the solutions to reduce the shrinking risks. If the non-uniform part is inevitable, then the mold should be designed to make material flow within the mold travel from thick to thin.

Original DesignOptimal Design Original DesignOptimal Design

Plastic in thin wall thickness cools and solidifies fast, while plastic in thick cools slow, making it possible to generate sink marks.

3. Design the reasonable ribs thickness

Shrinking occurs where there are thick ribs. Design the ribs with features, such as U groove, height difference, hackly groove, etc., to reduce the shrinking.

U Groove Height Difference Hackly Groove

4. Follow the design guidelines for boss

A boss is a mounting feature that will hold a screw or thread-forming screw. If the boss design doesn’t follow the design guidelines, the sink marks are likely to be caused as the boss might thicken the wall. Here are the design guidelines to help you get the qualified parts.

Collaborating with a Reliable Partner

For a skilled engineers, shrinking risks on product design can be easily analyzed through extensive experience, or the simulation software. But if your product design is frozen, the expert engineer is still able to prevent the product from shrinking. For instance, relocating gate that makes the melt plastic go from thick to thin, reasonably designing mold cold runner system, adjusting the parameters during injection molding process, etc., to make your part meet your expectations. Therefore, collaborating with an experienced manufacturing supplier is a crucial precaution to mitigate the risks of receiving products with defects. RPWORLD is committed to manufacturing technologies through injection molding and CNC Machining with almost 20 years. If you’d like to talk about your project with our engineer, CONTACT US to get free DFM analysis for your part design.

CONTACT US to get free DFM analysis for your part design.