Have you considered optimizing the part design to increase part quality, while cut down the manufacturing cost and time? There are design tips about ribs and undercut you could refer to.

Ribs is an indispensable feature in the plastic injection molded parts. It is used to increase the strength of parts, facilitate the plastic melt flow as flow channel, and provide guidance, positioning and support for other parts in the product.

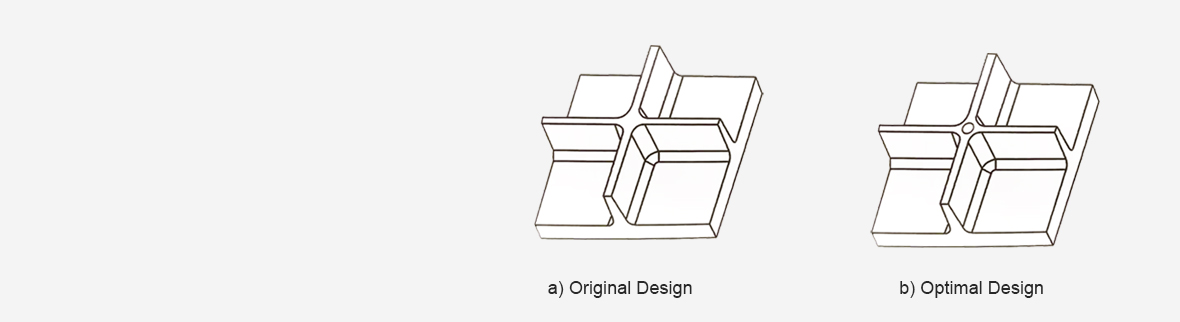

1. Ribs design should abide by the principle of uniform wall thickness.

As shown in the figure, the bearing cap needs to be manufactured. In original design, if it is clamped at A, the general claw is not long enough, and it is not easy to clamp at B. In optimized design, B, the original circular conical surface is changed to the cylindrical surface C, which is easy for clamping. Or adding a cylindrical surface D for easy clamping.

The wall thickness of part will be too thick when the corner at the joint of ribs is round, so the thick wall thickness will cause shrinkage on the part surface. In optimal design, hollowing out the partial wall thickness to maintain the uniform wall thickness and avoid the shrinkage of surface.

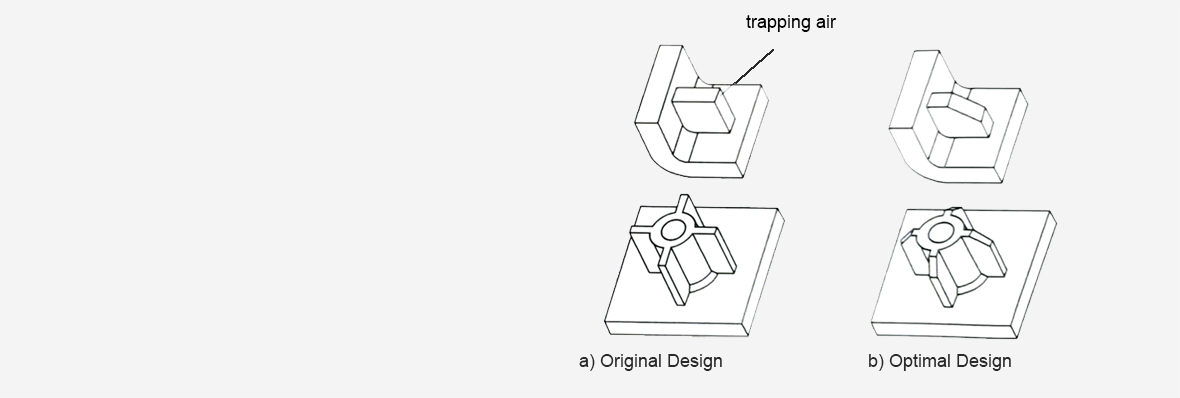

2. Adding the bevel to the top of ribs in order to avoid trapping air.

In original design, the right angle at ribs top will generate trapping air, and brings about injecting difficulty and defects. While in optimal design, it could avoid the trapping air at ribs top to add bevel angle or rounded angle.

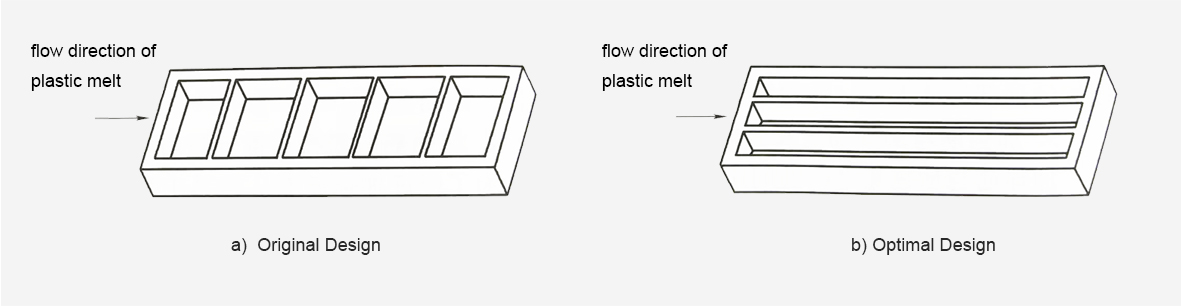

3. The direction of the ribs is consistent with the flow of the plastic melt.

The direction of the ribs should be consistent with the flow direction of the plastic melt, thus to ensure smooth flow of the melt, improve injection efficiency, and avoid injection defects such as air trapping.

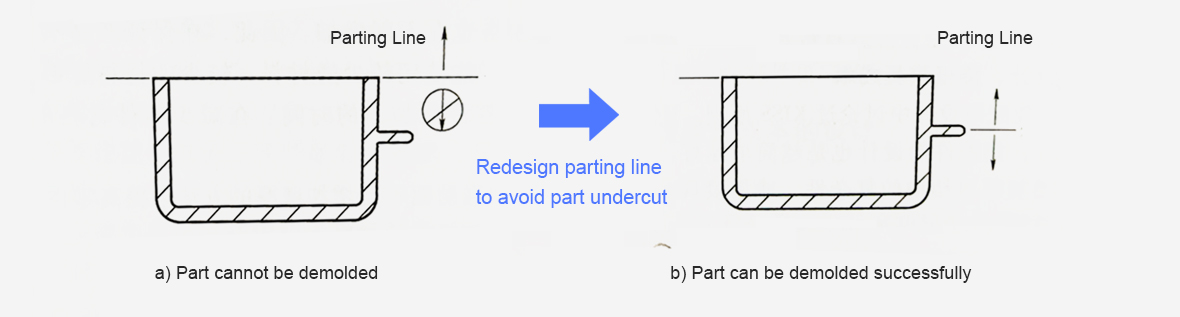

In mold, undercut can be realized successfully by Parting Lines and Side-Actions, which are more complex injection-molded geometry, and the important factors in increasing the mold cost. So, to reduce the mold cost, it is an efficient way to avoid undercut design.

4. Several outside undercut can be avoided by redesign the Parting Lines.

Take the following part for instance, the part can be demolded successfully by redesign Parting Lines.

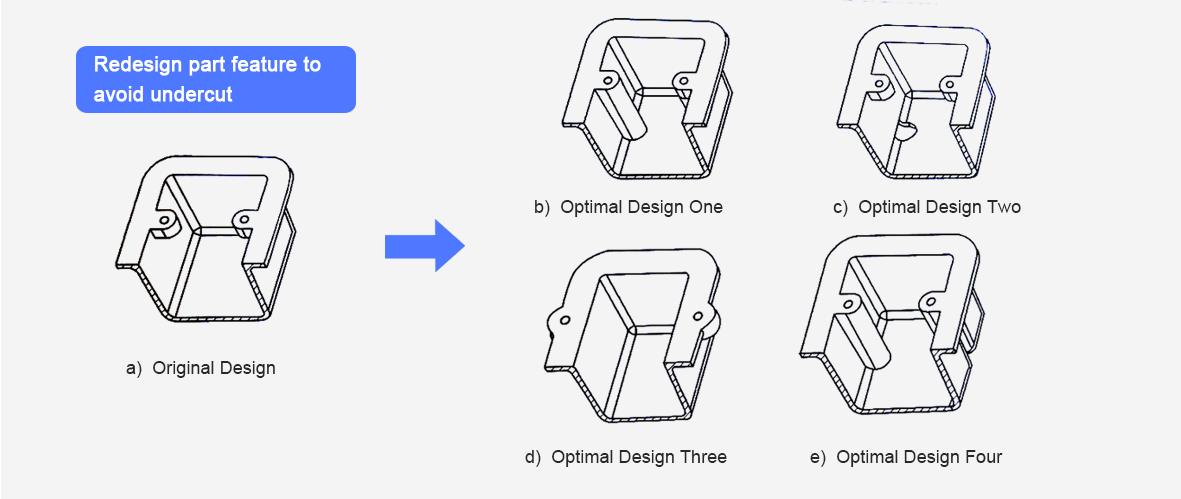

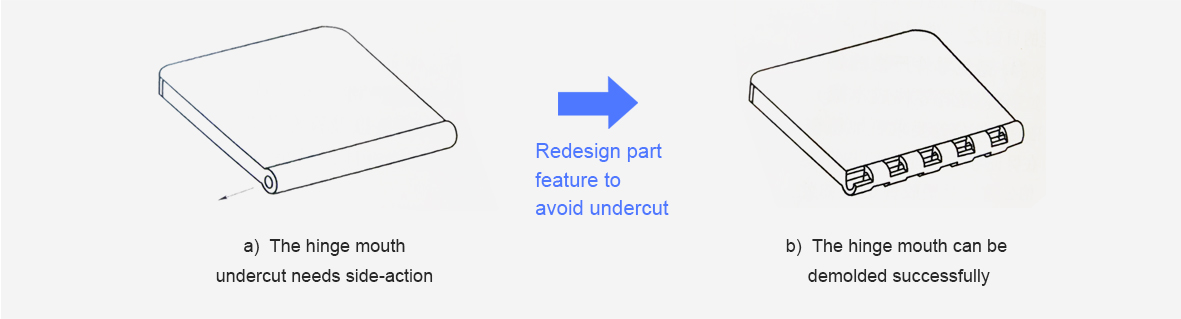

5. Redesign part features to avoid part undercut.

Many undercuts of part features can be eliminated by optimizing part feature design, and side-actions can be avoided, further reduce the mold cost.

6. Redesign part features.

There is undercut in part, which will be demolded by side-actions. While side-actions can be avoided by redesigning the part features, and four ways are shown in the optimal designs.