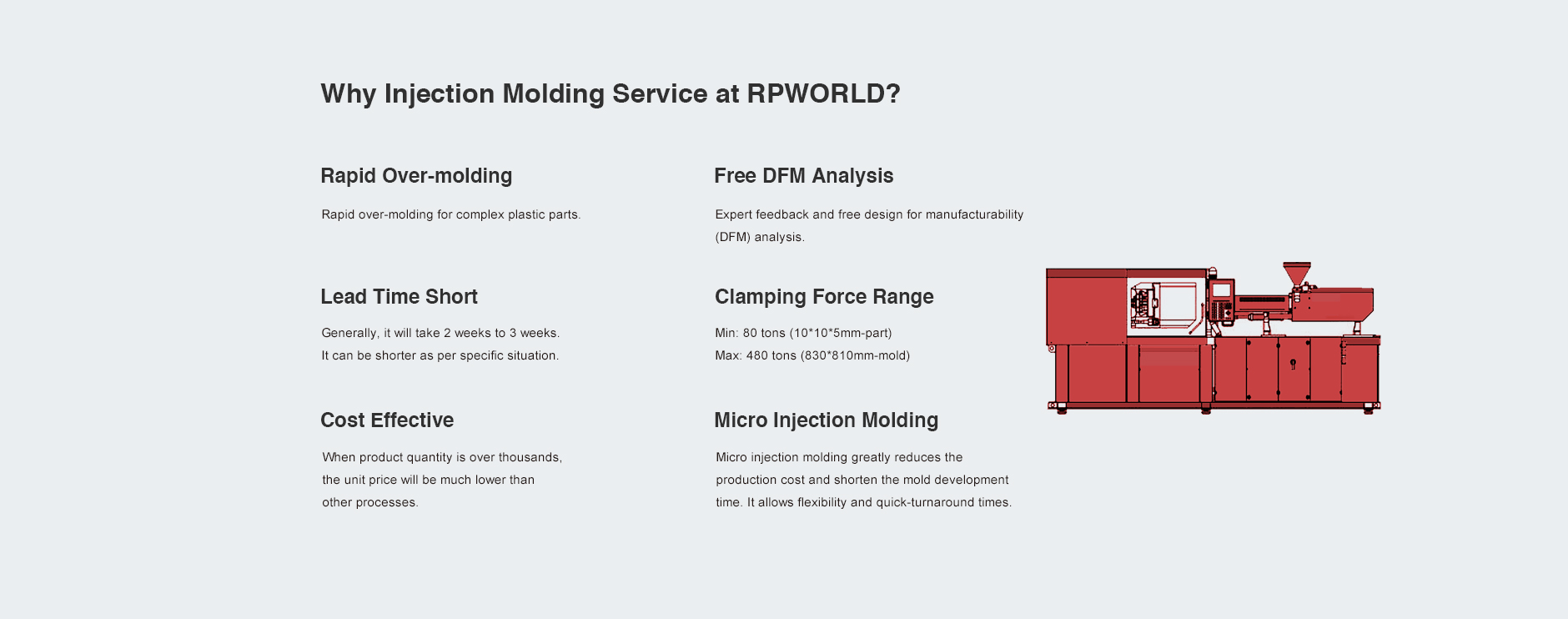

The injection molding process is the most common, most important and economical process for the mass production of plastics, especially high performance engineering plastics. We offer rapid tooling (prototype tooling), trial tooling ( bridge tooling ), hardened tooling, low volume production, high-volume production (mass production) and on-demand production.

The injection molding process is the most common, most important and economical process for the mass production of plastics, especially high performance engineering plastics. We offer rapid tooling (prototype tooling), trial tooling ( bridge tooling ), hardened tooling, low volume production, high-volume production (mass production) and on-demand production.

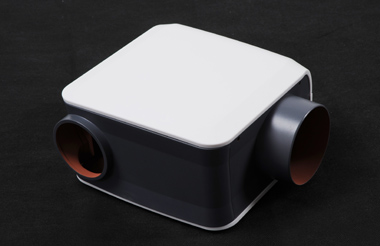

Injection molding is a manufacturing process for producing parts by injecting material into a mold. Injection molding can be performed with a host of materials, including metals, elastomers, and most commonly thermoplastic and thermosetting polymers.

Injection molding is hot popular for its high efficiency, complex part design, enhanced strength, flexibility material and color and lower cost.

RPWORLD has rich experience in injecting high-performance engineering materials. We stock common nylon with glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class, meeting all your needs for materials.

Take a tour through our production base to see RPWORLD rapid injection molding at work.

Click to upload your 3D files to get a quote.

Case Study

Case Study

RPWORLD supports a fast developing medical company in Europe from prototype to customized production for the high class eye diagnostics device...

DFMA

DFMA

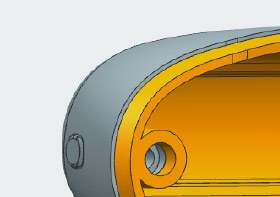

DFMA is designed to ensure product design at lower cost, shorter time and higher quality by improving product manufacturability and assimilability on the premise of taking product ...

Blog

Blog

The client asked for design with no screws, so we chose clips, however, the clip hook was broken during drop testing, what should we do?Learn how to design proper clips...