Products design is a challenging work. Designer must take every aspect into consideration, including product structure, materials selection, final applications, and even the competitors’ products. There is one more crucial factor—the requirements of manufacturing process for part design. You might wonder why does manufacturing process set boundaries on part design, and why don’t manufacturers just change it to other processes? But in fact, to transfer your design into a solid part with less time & cost-efficiency, you will have to think about the manufacturing process in designing.

This article explores the requirements of CNC machining process for part design and talks about 5 tips to machine parts with lower cost, high efficiency, high quality, under the conditions of meeting needs of product functions, appearance and reliability.

This article explores the requirements of CNC machining process for part design and talks about 5 tips to machine parts with lower cost, high efficiency, high quality, under the conditions of meeting needs of product functions, appearance and reliability.

1. Loosen Part Tolerance

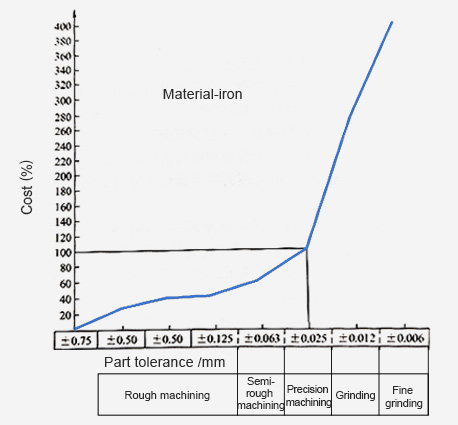

The tighter tolerance of the part, the higher cost of the part. This is the same for machining parts. See the chart below, as the increasement of requirements on part precision, more precision manufacturing processes are required, which followed by lower production efficiency and rising production cost.

It can be concluded that it’s better to avoid tight tolerance. The looser tolerance of the parts, the easier the part can be machined. How to change to loose tolerance? You can start from two sides.

a. The product geometry: there are many ways to avoid the part tight tolerance, like designing reasonable gaps, simplifying product assembly relationships, using positioning features, combining points or lines with surface instead of combining surfaces.

b. The part surface: the surface which has fewer precision requirements and lower quality should not be designed to the surface with high precision and high roughness. In addition, surfaces that do not need to be processed should not be designed as machined surface.

The relationship between the cost and tolerance of machining parts

2. Simplify Products and Part Structure

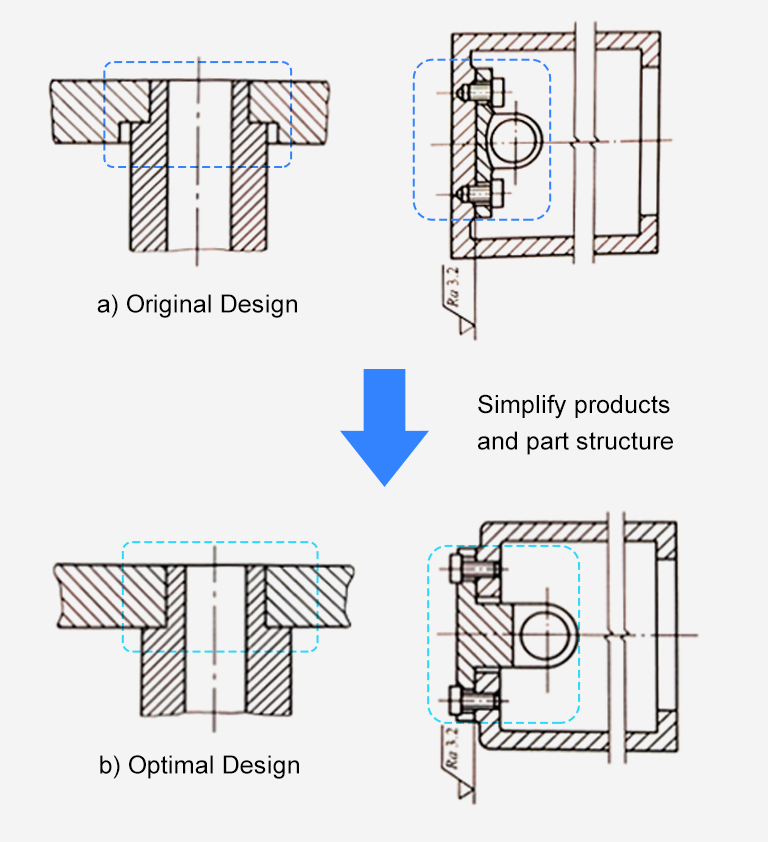

By reasonably splitting and combining products, the structure of products and parts is simplified, so that the whole product is easy to be machined, following by the improved processing quality and reduced production cost.

When designing the machining parts, it’s not enough to consider from the view of a single part, but it’s better to consider from the overall perspective of the product, considering the feasibility, production efficiency and machining cost of every part in machining. Through the reasonable splitting and combining of products, simplifying products and parts structure, the entire products will be easily machined with high quality and lower production cost.

In original design, the complex geometry structure is time-consuming in machining, while the simple-structure part in optimal design reduces processing cost and raises production efficiency.

When designing the machining parts, it’s not enough to consider from the view of a single part, but it’s better to consider from the overall perspective of the product, considering the feasibility, production efficiency and machining cost of every part in machining. Through the reasonable splitting and combining of products, simplifying products and parts structure, the entire products will be easily machined with high quality and lower production cost.

In original design, the complex geometry structure is time-consuming in machining, while the simple-structure part in optimal design reduces processing cost and raises production efficiency.

Simplify products and part structure

a) Original Design

b) Optimal Design

3. Reduce the Manufacturing Difficulty

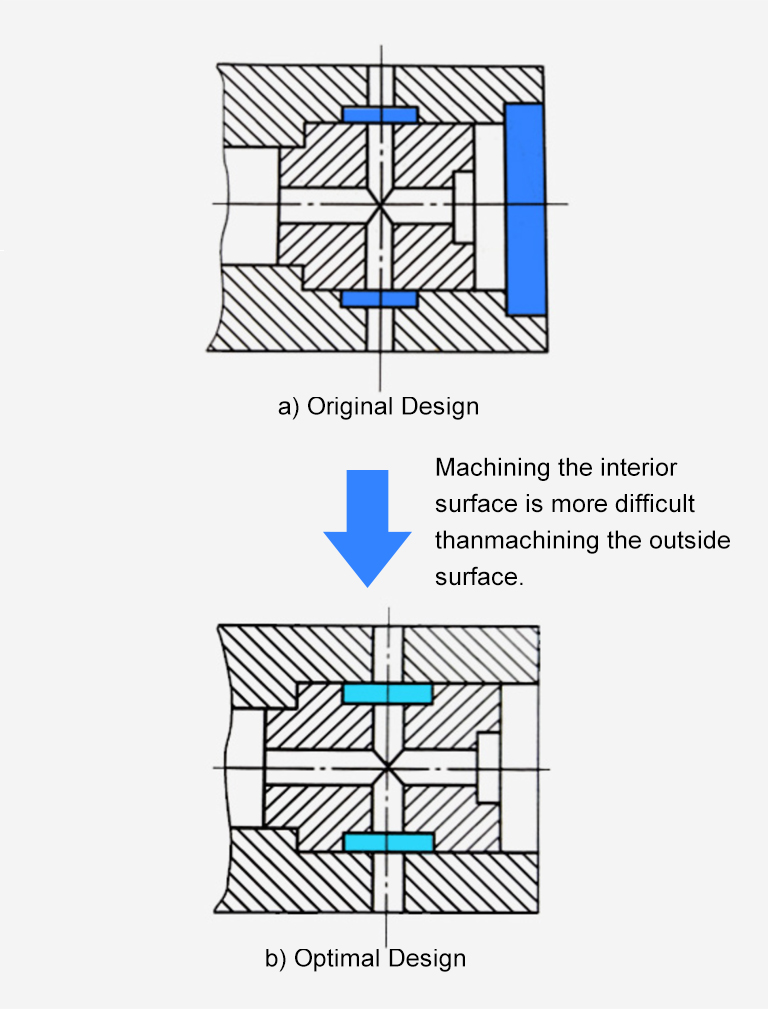

There’s no doubt that it is difficult to machine the inner surface than the outer surface. Therefore, the parts should be reasonably designed to reduce the machining difficulty.

See the original design as shown below, it's difficult to machine an interior annular groove. While in optimal design, it’s easy to machine the outside surface of the part and does not impact application.

See the original design as shown below, it's difficult to machine an interior annular groove. While in optimal design, it’s easy to machine the outside surface of the part and does not impact application.

Machining the interior surface

is more difficult than

machining the outside surface.

is more difficult than

machining the outside surface.

a) Original Design

b) Optimal Design

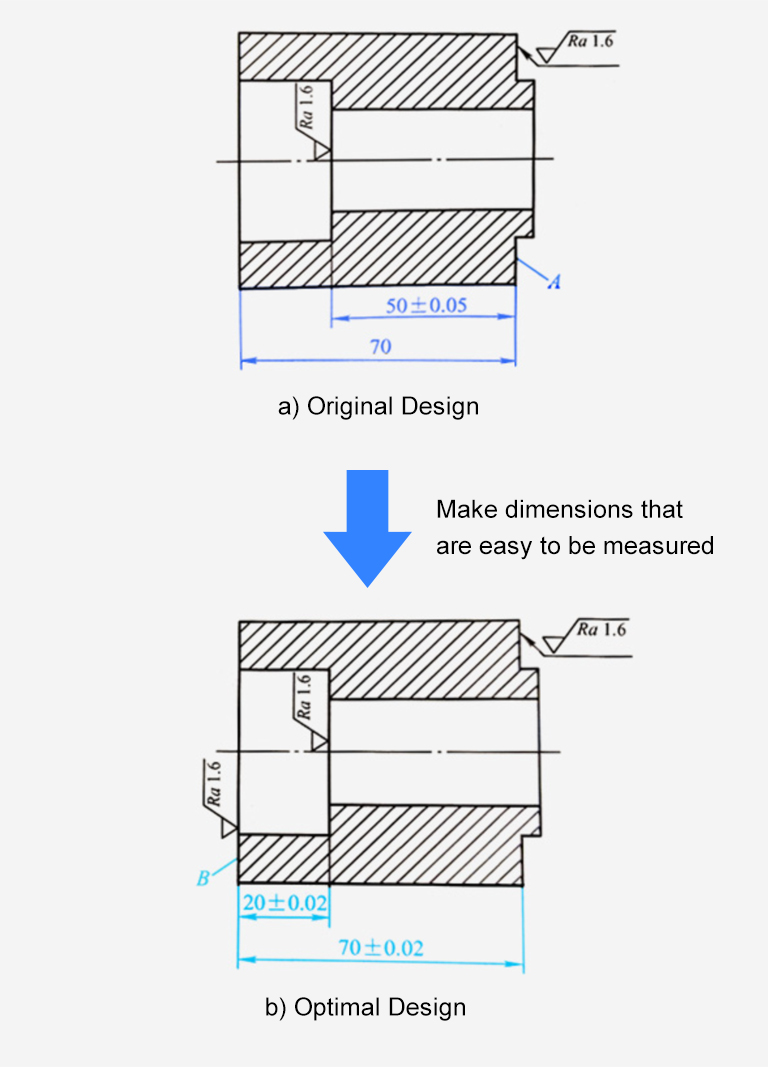

4. Make Dimensions that are Easy to be Measured

When marking the parts drawings of machined parts, the marked dimensions should be easy to measure.

See the original design in shown below, the dimension datum is side A, which is not easily to be measured; while in the optimized design, the dimension datum is side B, which is convenient for measurement.

See the original design in shown below, the dimension datum is side A, which is not easily to be measured; while in the optimized design, the dimension datum is side B, which is convenient for measurement.

Make dimensions that

are easy to be measured

are easy to be measured

a) Original Design

b) Optimal Design

5. Try to Avoid CNC Machining Process

Yes, you can understand the meaning by words. CNC machining is relatively costly and time-consuming in production and doesn’t allow for the extreme complex-geometry parts. In the increasing industries, CNC machining has been replacing by more manufacturing processes, such as injection molding, stamping, die casting, etc. Therefore, a product designer has to ask a question that is it possible to use other manufacturing processes instead of CNC machining.

Are those tips inspiring your design? More design guidelines and tips about machining parts to accelerate your cost-efficient product development life cycle, please follow our BLOG, CONTACT US to share your thoughts.