Product design is the core of the entire industry chain, producing the maximum added value. While the product manufacturing is at the bottom of the industry chain, it generates the minimal added value.

The reason is that product design, lying at the core and very important position in the product development, determines product cost, quality and development cycle. And the latter three ones are the factors to measure the success of product development. High product quality, low product cost and short product development cycle are the keys to success in the fiercely competitive market.

1. PRODUCT DESIGN DETERMINES ITS COST

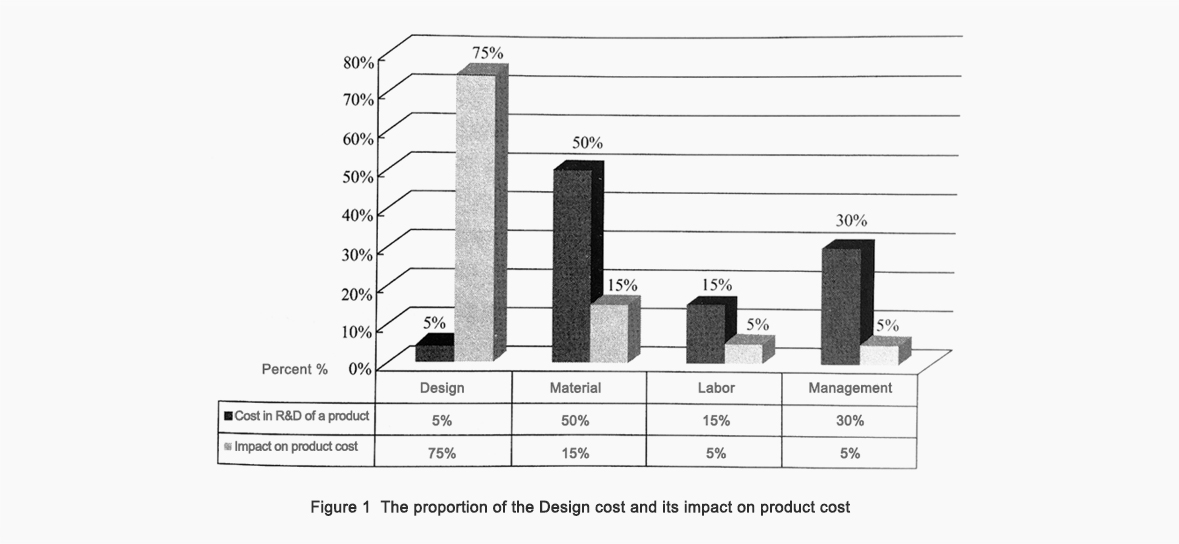

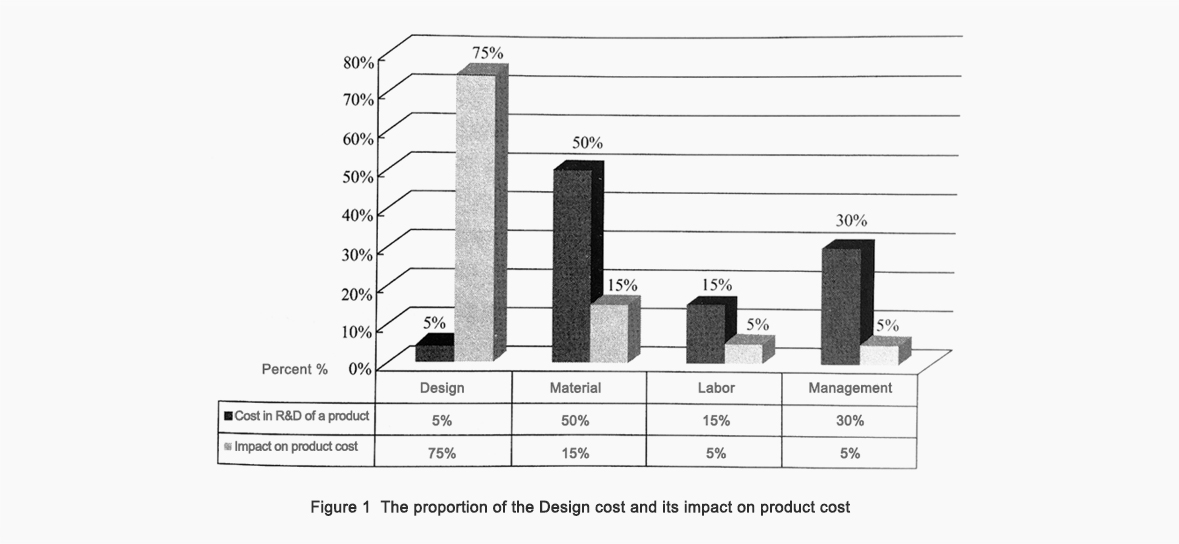

There are four main factors affecting product cost, namely, design, material, labor and management. In the product development process, the proportions of the cost for the four factors and their impact on product cost are shown in the table below:

The table shows us:

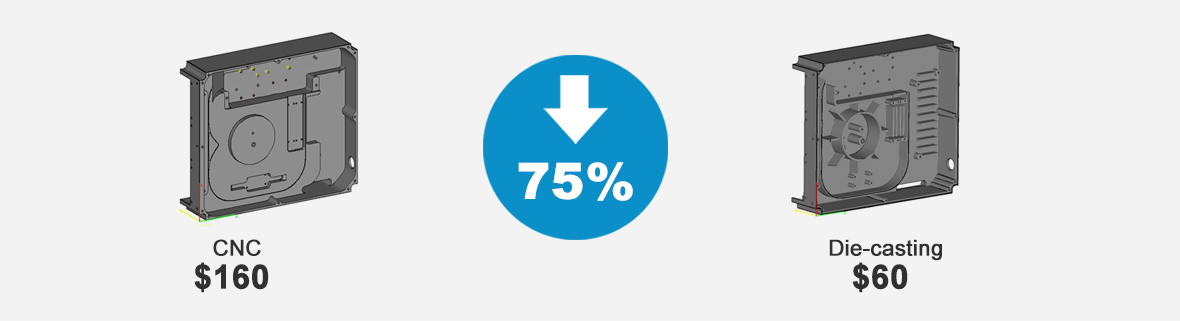

1) The cost of product design only accounts for 5% of the total product development cost.

2) Product design determines 75% of product cost.

3) Product design affects the cost of material, labor and management to a large extent.

4) Without product design optimization, material, labor and management have little impact on reducing product cost.

2. PRODUCT DESIGN DETERMINES ITS QUALITY

1. Quality has no limitslow density, high strength, the most usual material in automation equipment. Different grades has different properties. 5052 mainly used for sheet metal, 6061 for CNC machining and the widely used material. Normally 6063 is aluminum section, 7075 is aviation aluminum for high strength occasion. Anodizing is the most common surface treatment for Aluminum alloy.

2. Determinants of product quality

Since product quality is so important in a competitive market, where does product quality come from?

Does the quality come from manufacturing?

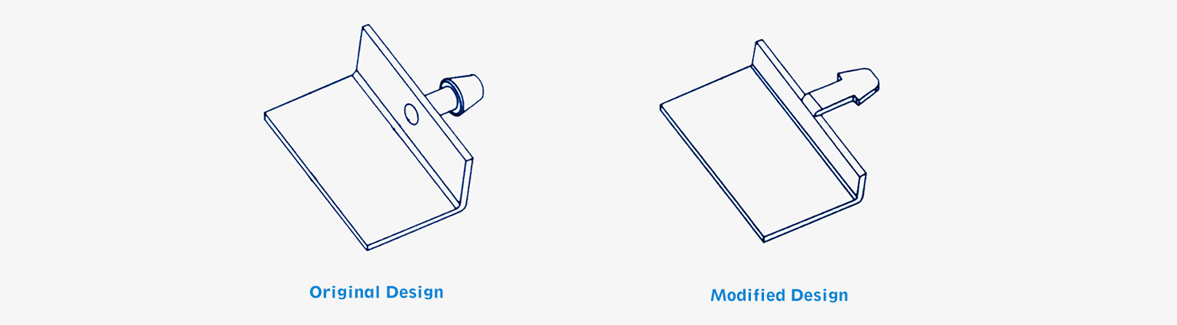

No. Products are manufactured according to designs and processes. If a product design is not reasonable, it is impossible to produce high quality products no matter how precise the machines and how outstanding the engineers are.

Does the quality come from inspection?

No. The inspection is to pick out the Not-Good products according to the inspection standard after the products are manufactured. Even by improving product inspection standard, product quality can be improved, however, product defect rate will increase meanwhile, which results in an increase in product cost. This development cannot solve the problem fundamentally.

Does the quality come from design?

Yes. Product design determines the product's genes and the product quality.

There is a "80/20 Rule"( Pareto Principle) which vividly illustrates the importance of product design to product quality. Statistically, it’s reported that about 80% of product quality issues are caused by designs, and 20% are caused by manufacturing and assembly. In other words, if the product design is perfect, 80% of the product quality issues can be avoided; no matter how perfect the manufacturing is, only 20% of the product quality problems can be avoided, and the other 80% can't be solved.

3. PRODUCT DESIGN DETERMINES ITS DEVELOPMENT CYCLE

Product design determines its development cycle. A reasonable product design can be smoothly manufactured and assembled, while an unreasonable design often results in the unfeasibility of product manufacture or assembly, and results in an extended product development cycle. Especially in mass production, many parts are manufactured by molds (such as injection molds, etc.). If the product design is unreasonable, the part cannot be manufactured smoothly or the quality of the part does not meet the requirements, then both the design and the mold need to be modified. The modification of the mold usually takes a lot of time, which leads to an increase in the product development period.