6 Essential Tips for Selecting

Reliable Mechanical

Parts Suppliers

Finding the right mechanical parts suppliers can be challenging, yet it's

crucial for your product development’s success. We've compiled essential insider tips to

help you simplify your search, ensuring you quickly identify the right and reliable manufacturing

suppliers. Let's explore these key considerations:

Manufacturing Capabilities

When selecting a supplier, it's crucial to evaluate their manufacturing

capabilities to determine if they align with your project's requirements:

● Single manufacturing process or one-stop solution: Some suppliers specialize in a single manufacturing

process, such as CNC machining or injection molding. A supplier offering one-stop manufacturing

solution, including CNC machining, injection molding, even surface treatment and Design for

Manufacturability (DFM) analysis, can be more advantageous. These suppliers can help reduce

communication challenges, and potentially lower costs and turnaround times.

Quality Assurance

Evaluating the quality assurance of a supplier for customized mechanical parts

is a complex process. It's crucial to look beyond just the supplier’s assurances. Key

considerations include:

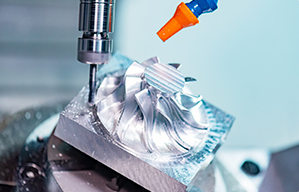

● Equipped Machines:A primary indicators of a supplier’s capability is their advanced manufacturing

equipment. The use of advanced injection molding presses and multi-axis CNC machines typically

results in higher precision and consistency in production.

● Automation: Automation significantly reduces human error, enhancing the consistency of production runs.

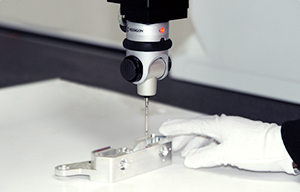

● Quality Control: Quality control isn't just about the final product; Suppliers should implement

stringent quality control and inspection equipment to ensure all stages of production meet the

required standards. Additionally, traceability in quality control should be provided for customer

reference.

● Packaging Solutions: Often overlooked, proper packaging is not only for the safe transportation of the

product but also for maintaining its integrity until it reaches the customer.

Responsive Communication

The importance of clear and timely service and communication during cooperation

cannot be overstated. The one-on-one professional engineering consultancy service, like having an

engineering expert by your side, is preferably. After all, having a manufacturing partner who can

provide expert advice and solutions tailored to your specific needs is much convenient than

communicating with customer service, or even no service at all.

Certifications

Evaluating certifications is a key step in assessing a supplier's

credibility to global standards. For instance, an ISO 9001 certification is an essential indicator

to demonstrate a supplier’s capability to quality management systems. And a Dun &

Bradstreet certification offers insights into a business's financial health and credibility.

More certifications related to specific needs:

● For the medical device manufacturing, ISO 13485 is essential to ensure the suppliers adhere to the

rigorous quality management systems required for medical device production.

● For automotive part supplier, ISO/TS 16949 certification ensures higher quality and global

competitiveness.

● For those who care about Environmental, Social, and Governance (ESG) standards, ISO 14001 certification

is a key to evaluate one of the factors, showing suppliers’ commitment to environmental

management and sustainable practices.

Long-Term Cooperation

It’s important to see if a supplier is interested in more than just a

transactional relationship. The suppliers qualified for long-term cooperation are ready to

understand your needs and adapt as they evolve, especially for product development from prototyping

ramping up to low-volume and full-scale production.

Business Reputation

Checking out a supplier's overall reputation is also necessary. Take a look

at reviews and what previous customers have to say about their experiences. Don't hesitate to

ask the supplier if they can connect you with some of their clients for a chat. It's a great way

to get the inside scoop on their reputation.

It's beneficial to combine customer reviews with information from national

company registration websites. Many countries provide free access to these databases, offering

insights into a company's financial stability and compliance history, which can be crucial in

evaluating their reliability and reputation in the market.

Why RPWORLD is Your Reliable Partner for Mechanical Parts?

At RPWORLD, we take pride in being more than just a mechanical part supplier

— we are your reliable partner in your supply chain journey. A few reasons why you can work

with us:

● Comprehensive Manufacturing Solutions: RPWORLD offers a one-stop solution, from rapid prototyping to

on-demand production, ensuring flexibility for evolving projects.

● Rigorous Quality Controls: We maintain stringent quality controls at every step and provide traceability

with FAI and COA reports for consistent quality.

● Interactive Service: Our responsive one-on-one engineering consultancy is tailored to your specific

needs, enhancing collaboration.

● Certified Supplier: RPWORLD holds ISO 9001, ISO 13485, and ISO 14001 certifications, demonstrating our

commitment to high quality.

● Long-Term Partnership: We prioritize building lasting relationships, adapting to your evolving needs

from prototyping to mass production.

We invite you to visit our state-of-the-art facilities and experience the RPWORLD difference for yourself. Contact Us today to kickstart your project today.