Finding the right supplier for product development and manufacturing can be a challenging and time-consuming task. Some suppliers offer batch production, but this applies to products with a frozen design that cannot be modified. But jumping straight from part design to batch production can be a risky move. Another type of supplier provide single or limited manufacturing services. And product developers have to find more manufacturing suppliers to support along the product development life cycle. At RPWORLD, we offer one-stop shop solution for product development, prototyping, and production, whether it is for low or high volumes.

With over 20 years of experience and expertise in manufacturing, RPWORLD has served industries, such as: automotive OEM, Tier I, and Tier II suppliers, biotech & medical device and more. Our four manufacturing solutions provide customers with flexibility and rapidity for all their manufacturing needs.

CNC Machining with High Precision and

Complex Structures (10-1,000pcs)

RPWORLD CNC machining is designed for customers who require precision machined parts with complex structures in medium-to-small volume production runs. With tons of 3-, 4- and 5-axis CNC machines, RPWORLD is capable of producing parts that meets DIN ISO 2768 M (F) standards. Ranging from 10 to 1,000 pieces, RPWORLD CNC machining delivers your accurate and consistent parts in as fast as 3 dasys

CNC Turning for High-Volume

Production (Diameter up to 44mm)

RPWORLD CNC turning, a cost-effective manufacturing process for cylindrical parts that are structurally simple. With expertise in high-volume production of machined parts up to 44mm in diameter, we ensure consistent quality and fast turnaround times using advanced equipment and techniques. This service is perfect for customers who require a high volume of small CNC machined parts for their products.

High-Volume Injection Molded Parts

With advanced injection molding equipment and our engineering experts dedicated to finding ways to increase production, such as using multi-cavity molds, our injection molding is designed for customers who require large quantities of small injection moled part. And you can also expect the consistent quality from the fast delivery in as fast 7 days.

Prototyping with Multiple

Manufacturing Processes

For prototyping needs, RPWORLD uses a range of manufacturing services, including CNC machining, injection molding, vacuum casting, sheet metal fabrication, finishing options, and more. We are committed to producing complex-geometry prototypes with most fitted process, for industries such as medical devices and automotive components, and can meet your exact specifications.

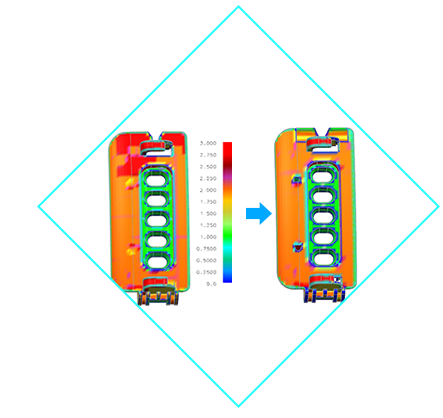

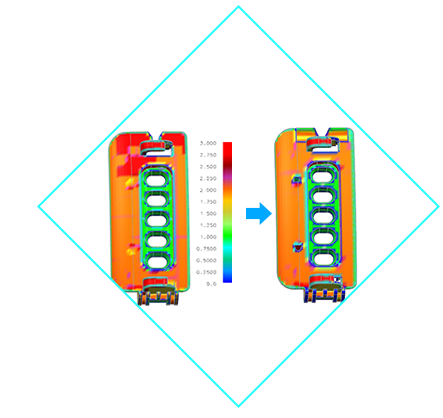

Free & In-depth DFM Analysis

In addition to multiple manfuactuirng processes, RPWORLD also provides Free and Comprehensive DFM analysis for every order. The DFM report includes suggestions for the process, material, surface treatment selection and design optimization from the perspective of manufacturability and assembly. The in-depth analysis helps reduce manufacturing risks before any actual production begins, avoid the costly reworks, and is one of the core benefits for customer to work with RPWORLD.