How On-Demand Manufacturing

Powers Unmanned Logistic Vehicles Revolution

The development of unmanned logistic vehicles is revolutionizing last-mile

deliveries! However, these vehicles, equipped with advanced technologies like artificial

intelligence and autonomous navigation systems, have faced significant investment in their research

and development. In this article, let’s delve into how on-demand manufacturing holds the

potential to accelerate the development of unmanned logistic vehicles, leading to more efficient and

agile industry practices.

The Need for Rapid Development

As e-commerce continues to soar and consumer expectations for fast and efficient

services rise, traditional logistic systems are facing significant challenges. Unmanned logistic

vehicles offer a solution by augmenting existing infrastructure and enabling faster and more

flexible delivery options. From autonomous drones for last-mile deliveries to self-driving trucks

for long-haul transportation, these vehicles offer increased speed, reduced operational costs, and

improved safety.

The need for rapid development of these vehicles is paramount to meet the

evolving demands of the industry, optimize resource utilization, and ensure timely and reliable

deliveries to customers worldwide. However, the lengthy and rigid manufacturing processes involved

in traditional vehicle production often delay the development and deployment of these technologies.

On-demand manufacturing addresses this issue by offering a streamlined and accelerated manufacturing

approach.

On-Demand Manufacturing Fuels Unmanned Logistic Vehicle Development

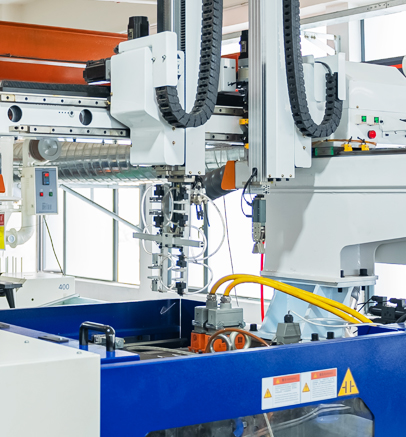

On-demand manufacturing is an agile and flexible approach that leverages

advanced technologies such as CNC machining, 3D printing and more to enable rapid prototyping and

end-use production of unmanned logistic vehicles. It can quickly help iterate designs, produce

vehicle components, and optimize performance. This agile manufacturing approach allows for faster

development cycles and facilitates the incorporation of emerging technologies into the vehicles.

● Customization and Scalability

One of the key advantages of on-demand manufacturing is its ability to customize vehicles according to specific requirements. Unmanned logistic vehicles often need to adapt to various operating environments and cargo types. On-demand manufacturing enables the production of vehicles tailored to unique specifications, ensuring optimal performance and efficiency. Moreover, as the demand for unmanned logistic vehicles grows, on-demand manufacturing offers scalability, allowing for the rapid scaling of production without the need for extensive retooling or setup.

One of the key advantages of on-demand manufacturing is its ability to customize vehicles according to specific requirements. Unmanned logistic vehicles often need to adapt to various operating environments and cargo types. On-demand manufacturing enables the production of vehicles tailored to unique specifications, ensuring optimal performance and efficiency. Moreover, as the demand for unmanned logistic vehicles grows, on-demand manufacturing offers scalability, allowing for the rapid scaling of production without the need for extensive retooling or setup.

● Reduced Costs and

Time-to-Market

Traditional vehicle manufacturing processes involve significant upfront costs and long lead times. By contrast, on-demand manufacturing minimizes these hurdles. With the elimination of expensive tooling and reduced material waste through advanced manufacturing technologies, costs are significantly reduced. Additionally, the streamlined production process enables faster time-to-market, allowing manufacturers to respond swiftly to market demands and stay ahead of the competition.

Traditional vehicle manufacturing processes involve significant upfront costs and long lead times. By contrast, on-demand manufacturing minimizes these hurdles. With the elimination of expensive tooling and reduced material waste through advanced manufacturing technologies, costs are significantly reduced. Additionally, the streamlined production process enables faster time-to-market, allowing manufacturers to respond swiftly to market demands and stay ahead of the competition.

● Collaboration and

Innovation

On-demand manufacturing approach fosters collaboration and innovation within the unmanned logistic vehicle industry. By providing a platform for manufacturers, designers, and engineers to collaborate, share ideas, and access advanced manufacturing capabilities, on-demand manufacturing facilitates the development of cutting-edge technologies. This collaborative environment encourages the exploration of new concepts, materials, and designs, ultimately pushing the boundaries of unmanned logistic vehicle development.

On-demand manufacturing approach fosters collaboration and innovation within the unmanned logistic vehicle industry. By providing a platform for manufacturers, designers, and engineers to collaborate, share ideas, and access advanced manufacturing capabilities, on-demand manufacturing facilitates the development of cutting-edge technologies. This collaborative environment encourages the exploration of new concepts, materials, and designs, ultimately pushing the boundaries of unmanned logistic vehicle development.

About RPWORLD On-demand Manufacturing

RPWORLD's on-demand manufacturing capabilities have been accelerating the

emerging automotive product development, including new energy vehicles, unmanned vehicles, and

unmanned logistic vehicles. With extensive manufacturing experience, RPWORLD offers unparalleled

advantages in the following areas:

Shortest lead time:

RPWORLD guarantees a minimum lead time of just 3 days, ensuring quick delivery of parts and components.

RPWORLD guarantees a minimum lead time of just 3 days, ensuring quick delivery of parts and components.

Customized CNC machining and injection molding:

RPWORLD specializes in providing tailored manufacturing solutions to meet specific requirements.

RPWORLD specializes in providing tailored manufacturing solutions to meet specific requirements.

One-stop manufacturing solution:

RPWORLD handles all stages of production, from prototyping to end-use production, from quality control to surface treatment.

RPWORLD handles all stages of production, from prototyping to end-use production, from quality control to surface treatment.

Design for Manufacturability (DFM) services:

RPWORLD's in-depth DFM services minimize manufacturing risks and ensure smooth production.

RPWORLD's in-depth DFM services minimize manufacturing risks and ensure smooth production.

Don't miss out on the opportunity to accelerate your project development

– Reach Out to

RPWORLD and embark on a more efficient and agile journey towards success.