Try to use the standard parameters in your part design, and the same parameters should be as consistent as possible. Wonder why? When the standardized parameters like the hole diameter, taper, threaded hole diameter and pitch, gear modulus and pressure angle, arc radius and groove are applied in design, the standard tooling, clamps and measuring tools can be used to reduce the specialized operation and realize time and cost efficiency in manufacturing. There are 5 design cases you may refer to.

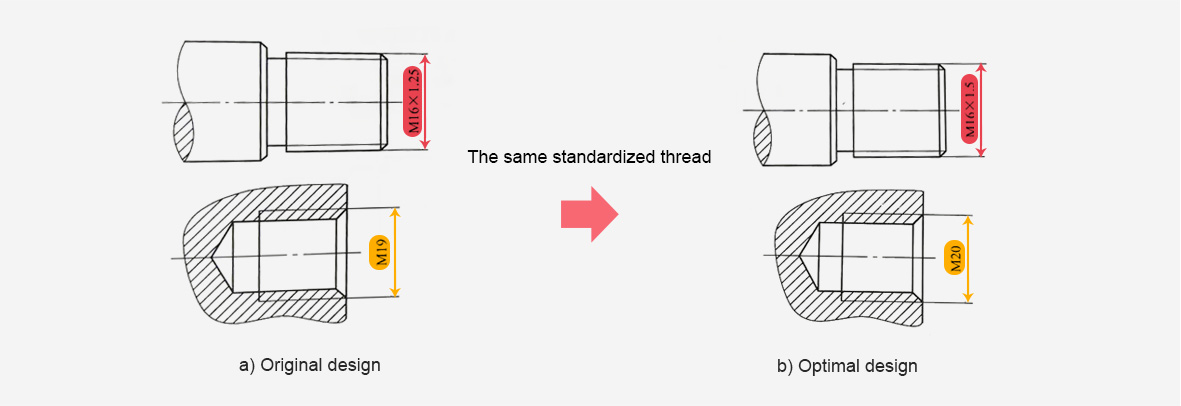

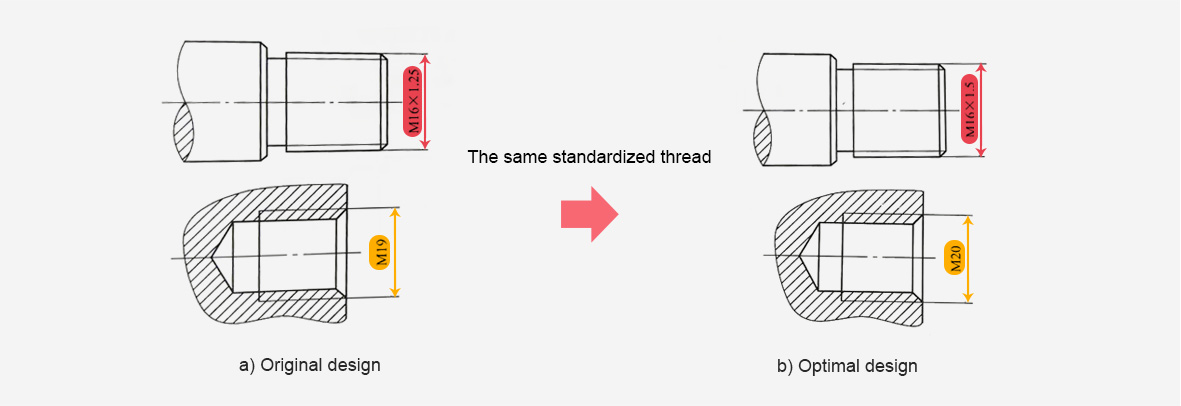

Standardized parameters should be applied when designing thread. So, the standard taps and threading dies can be used in processing.

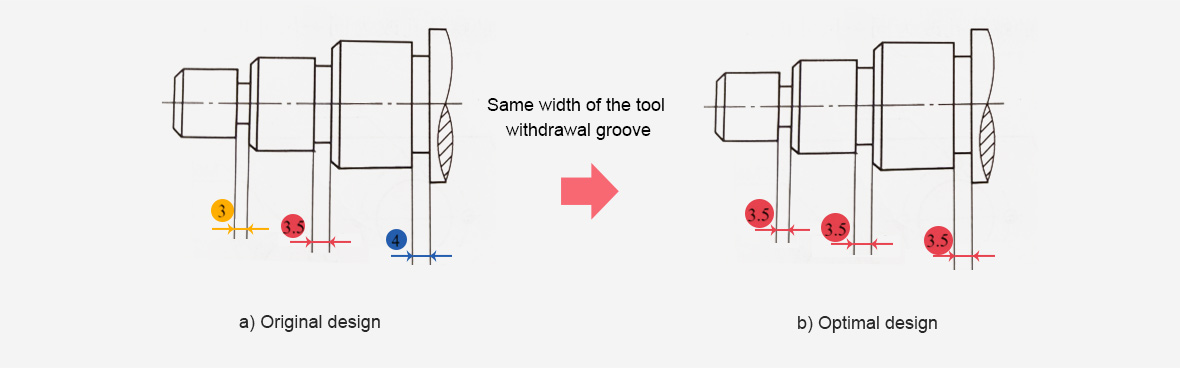

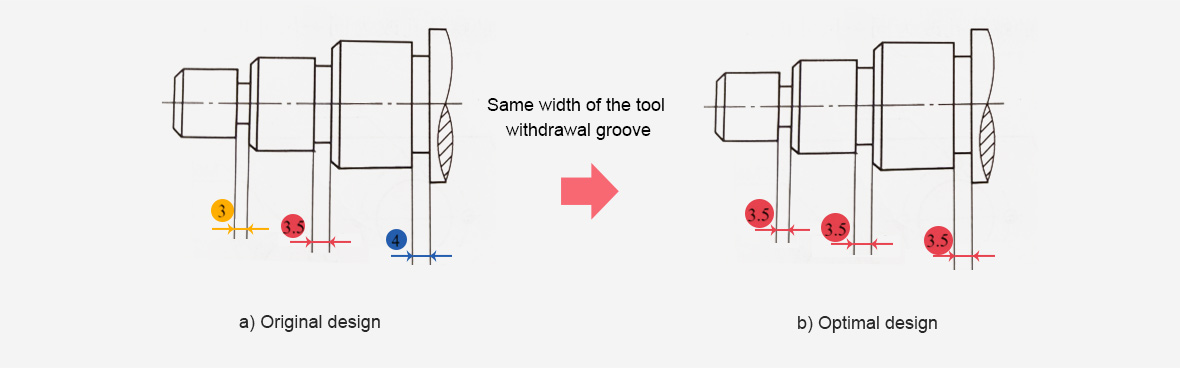

In the original design, the width of the tool withdrawal groove on the axis is different. It needs to replace the different widths grooving knives during turning, which increases the times of tool changing and setting. In the optimal design, the width of tool withdrawal groove is the same size. And all the grooves are processed with one tool, which reduces the type of tools and changing times, saving manufacturing time.injection molding, the local high temperature may degrade the parts, causing appearance defects. Adding radii is suggested to ensure the flow of plastic melt.

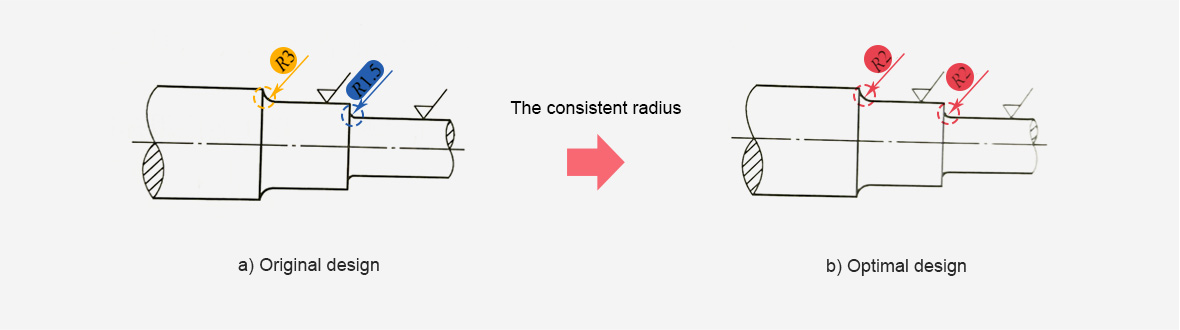

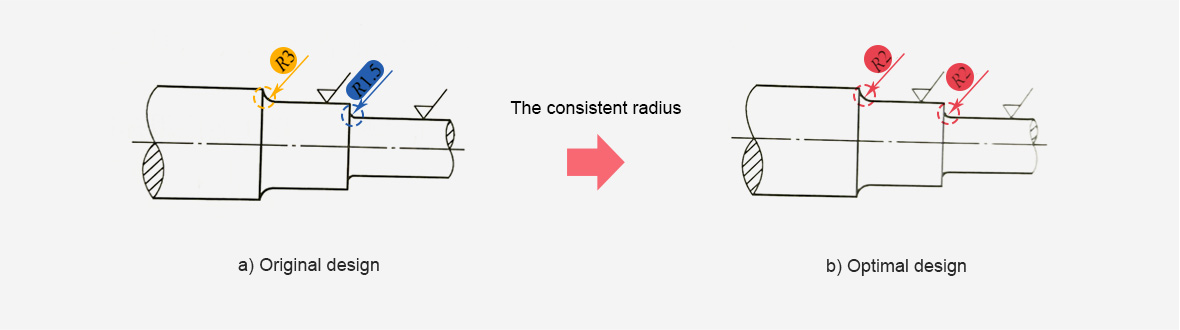

As shown in the figure, the transitional radius on the axis should be as consistent as possible to facilitate manufacturing.

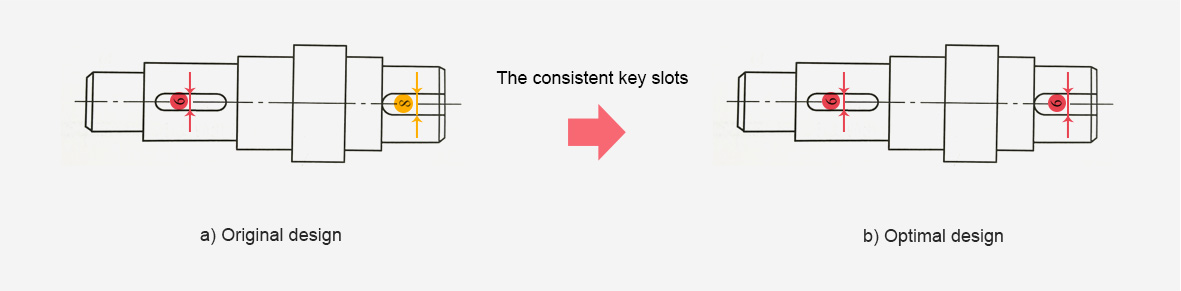

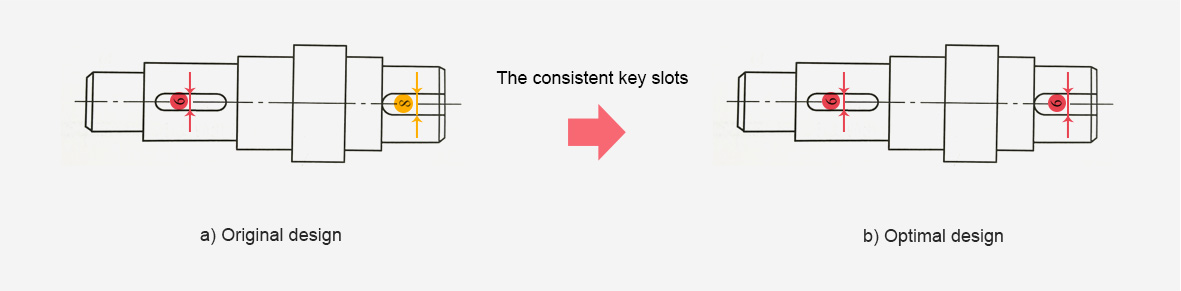

As shown in the figure, the same tool can manufacture all key slots, when they are designed to the same parameters.

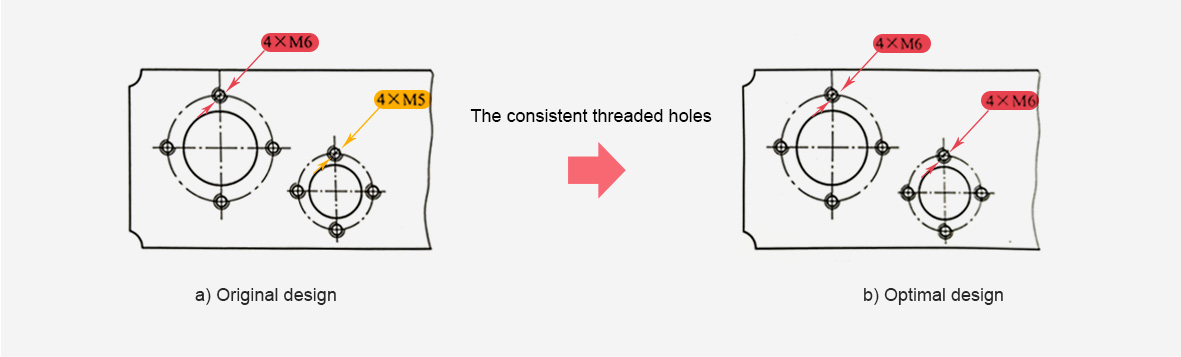

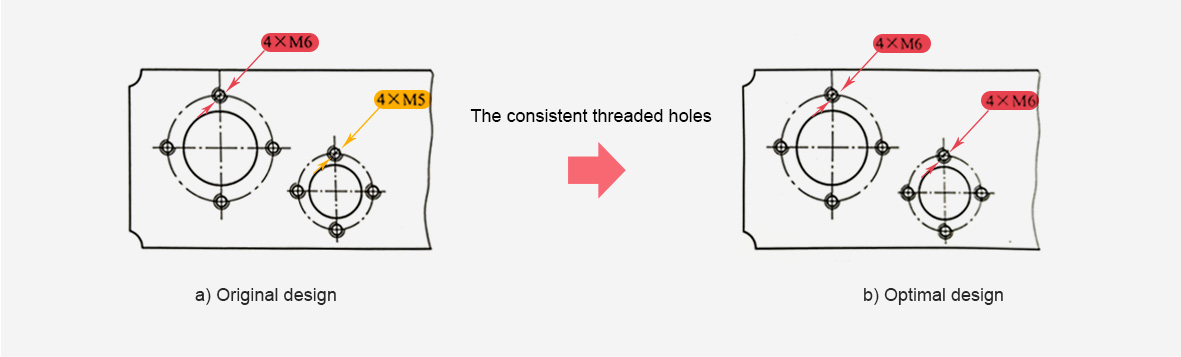

As shown in the figure, threaded holes of similar sizes on same end face are changed to the same size. It will be easy for processing and assembly.

Relevant Recommendations:

Holes designing are crucial for the connection of drilling parts, and it can directly affect the manufacturing difficulty and cost. To realize on-budget and time-efficient CNC manufacturing, here 5 design guidelines about holes for your CNC drilling parts.