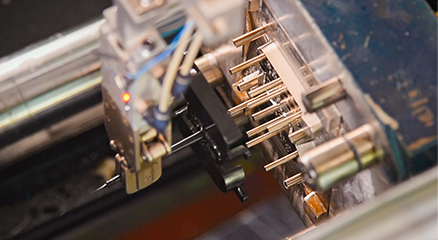

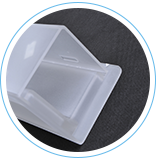

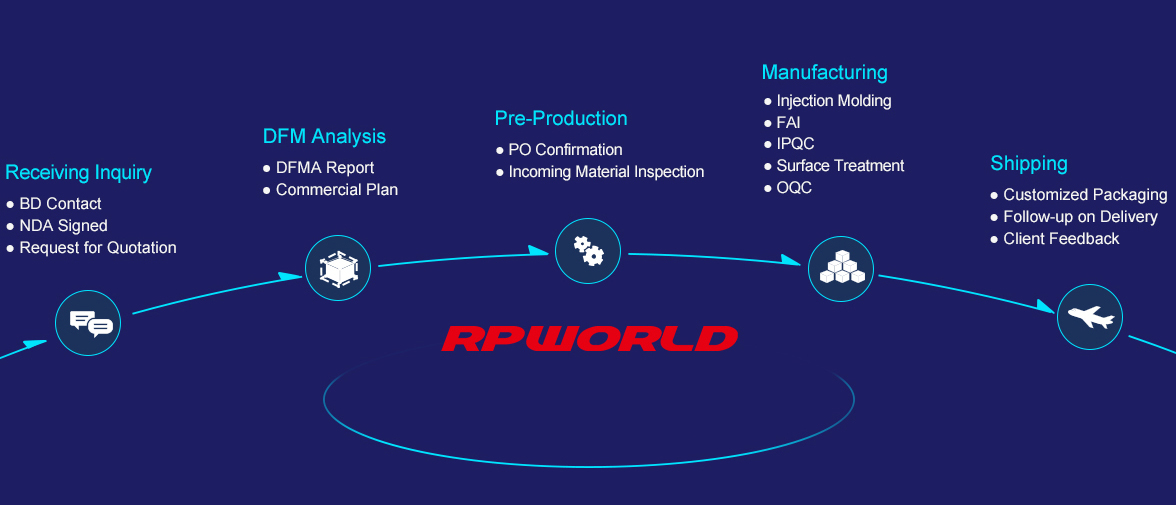

RPWORLD Custom Injection Molding in as Fast as 7 Days

Avoid Summer Delays with Our Shield Plan

$0

DFMA Report

$0

CNC Prototyping

72h

Turnaround Time

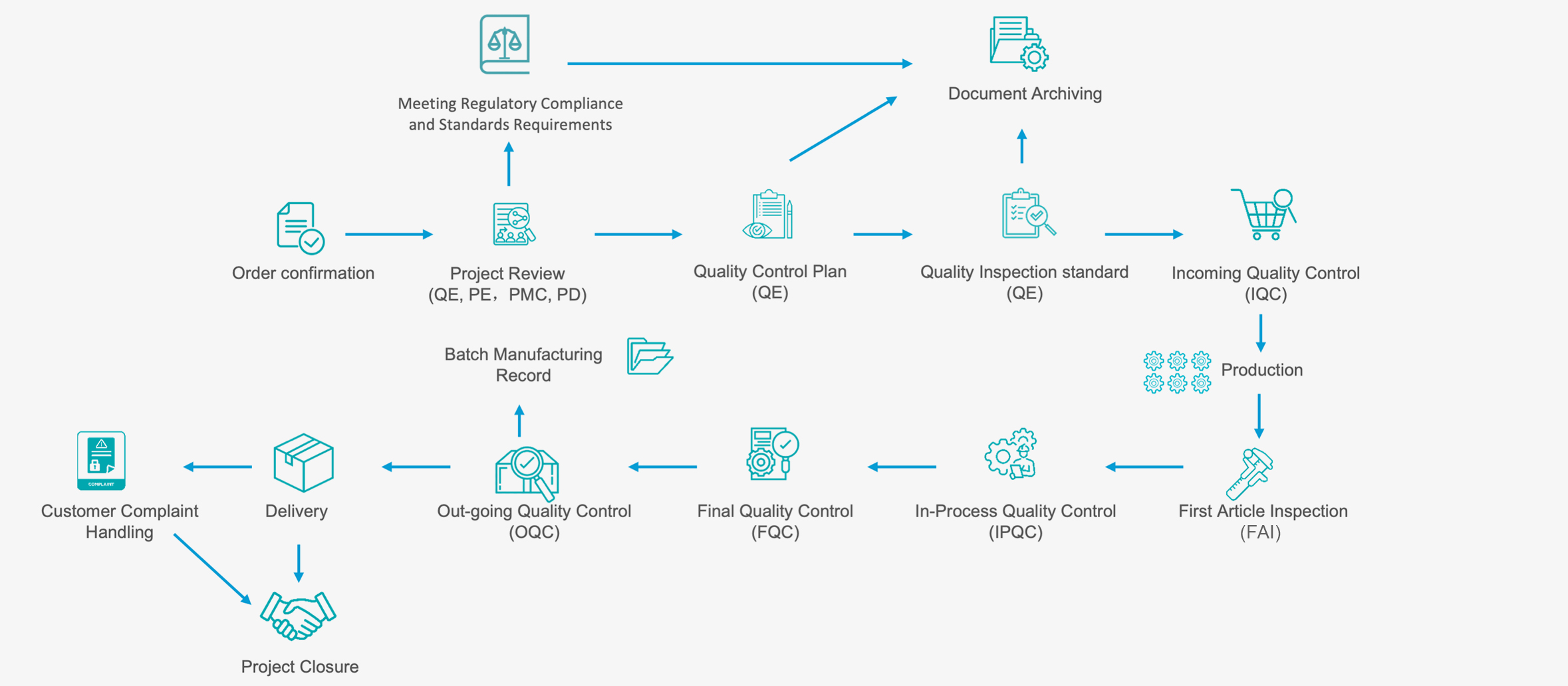

Certifications ISO 9001:2015 | ISO 14001:2015 | ISO 13485:2016

RPWORLD Custom Injection Molding in as Fast as 7 Days

Avoid Summer Delays with Our Shield Plan

$0

DFMA Report

$0

CNC Prototyping

72h

Turnaround Time

*For first-time enterprise injection molding orders

Certifications

ISO 9001:2015 | ISO 14001:2015 | ISO 13485:2016