RPWORLD Support from

Prototyping to Customized

Production

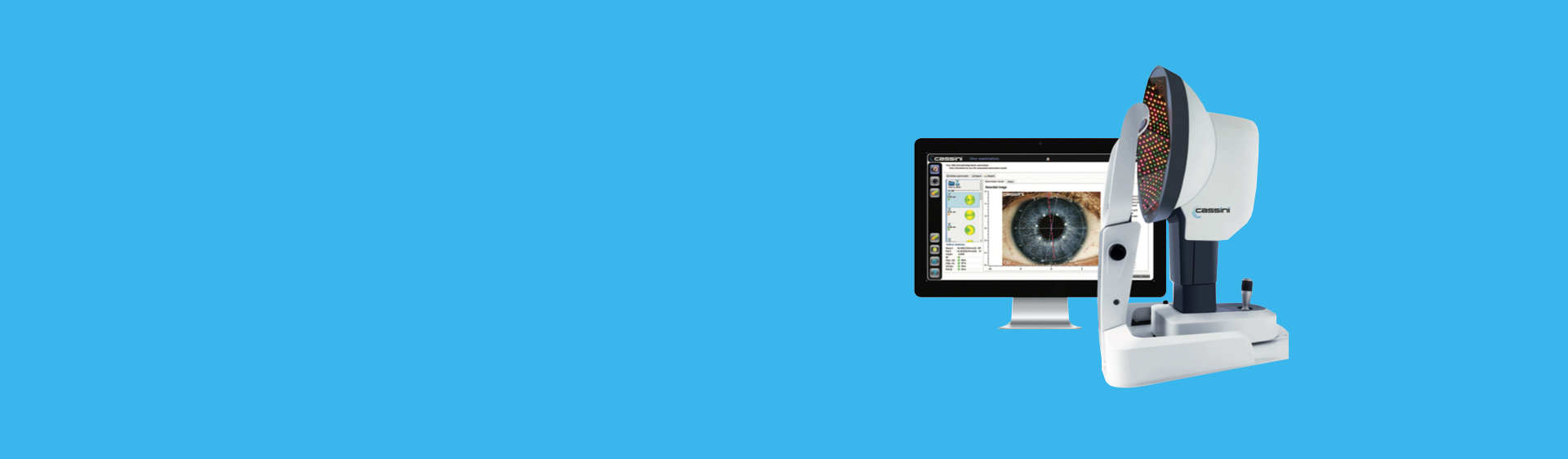

• PROJECT BACKGROUND

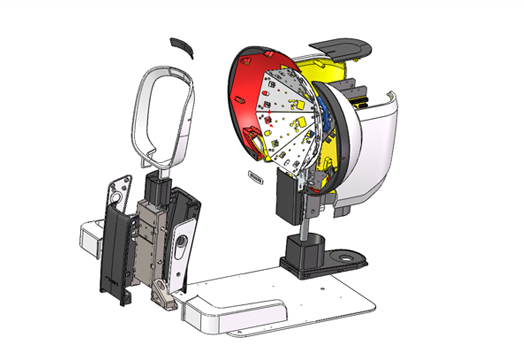

A rapidly-growing European medical device firm was looking for a partner for their high-end eye diagnostics device. Annual demand for this product is hundreds of units, with a design that could require modifications in order to respond to the changing market needs.

• CHALLENGES

• RPWORLD SOLUTIONS

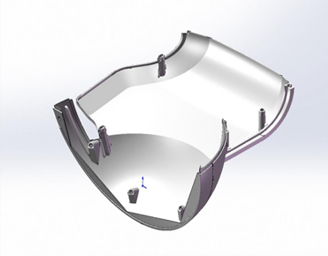

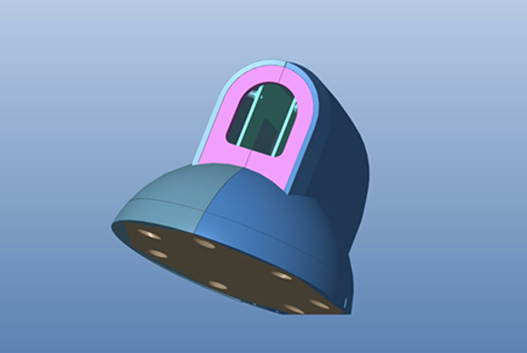

1. Process Selection:Combine urethane casting, injection molding, CNC and 3D printing.

(Traditional injection molding would require 2 to 4 months, cost over $100,000 and not permit major design changes once the mold has been made.)

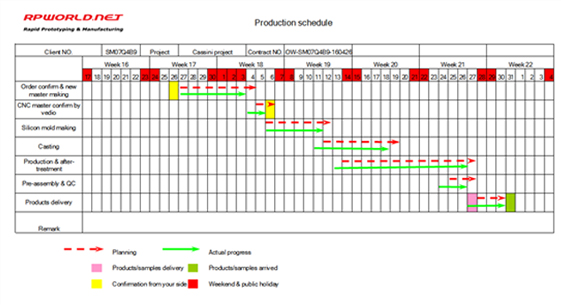

2. Project management:

We provided a dedicated project manager to oversee the entire project, ensuring timely delivery and addressing any issues that arose.

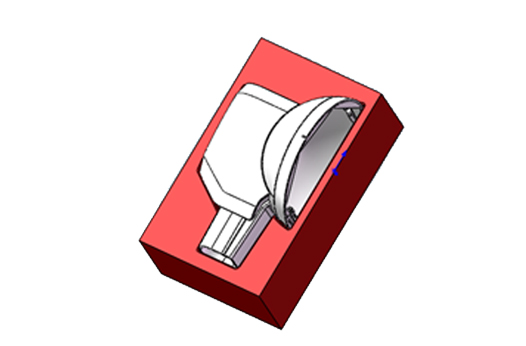

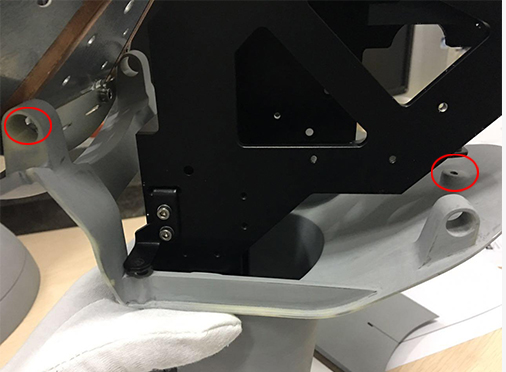

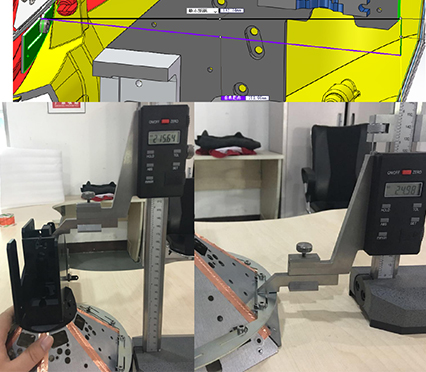

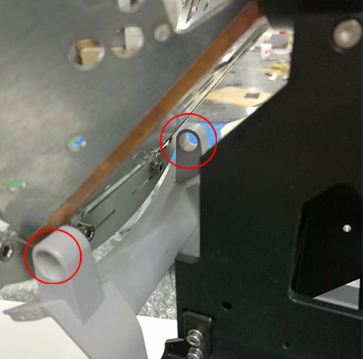

3. Produce fixtures and gauge tools to ensure accurate hole location, tolerances and final assembly.

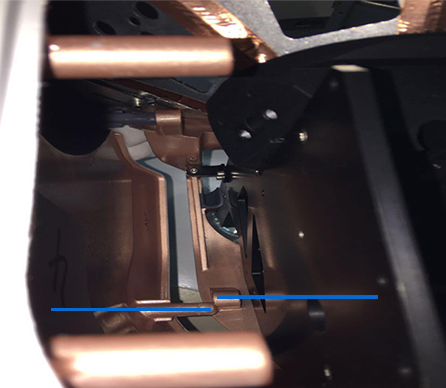

4. Cooper painting on the interior surface to achieve the EMC effect.

5. Customized Packing Solution: Designed by our engineering department for protection during shipment.

6. Engineering analysis and design optimization led to a successful product launch, with the client satisfied.

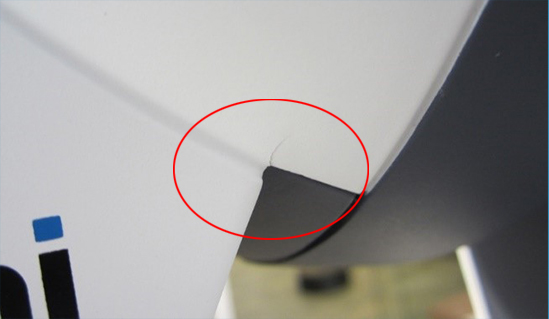

AFTER RECEIVING THE FIRST PRODUCT BATCH, THE CLIENT DETECTED A CRACK ON THE PRODUCT.

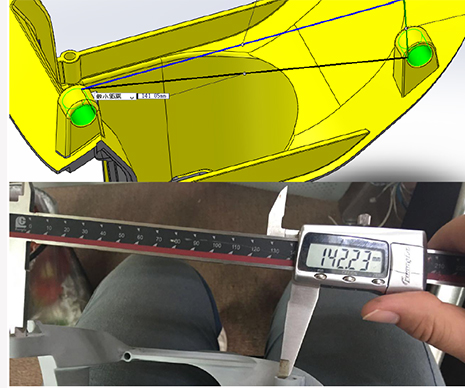

After further analysis, the client discovered that the rounded corner was smaller than what was specified in the 3D data (3D data R1.8 vs. measured size R1). The the round corner being too small led to stress concentration and cracking.

1. Assembly interference in the front, large gap at the back-end

2. Specified size 191.66mm, measured size 190.66mm (1mm difference)

3. Specified size 141.05mm, measured size 142.23mm (1.18mm difference)

4. Misalignment under free state

• CUSTOMER BENEFITS

• POSTSCRIPT NOTE

We completed this project through cooperation with Philips, who provided electronics prototyping support. RPWORLD provided hardware (housing and other components) support.

• FEEDBACK FROM THE CLIENT