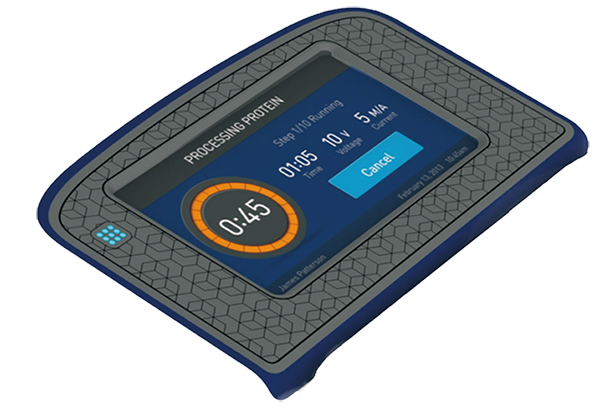

RPWORLD received a purchase order from an instrument company for a complete shell project for protein analysis and detection equipment. The customer advised us that we must deliver the demonstration prototypes to their office in Shanghai before 12 pm on April 28th. Timing was very tight as this instrument shell would be sent to the United States for the exhibition.

Prototypes for exhibitions are quite different from standard development prototypes as they have strict cosmetic appearance requirements. The project was quite complex, and considering the urgent deadline there was no room for mistakes.