Analysis of UL Flammability Standards I

Part I: Interpretation of UL 94 (the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances testing)

|

1. How to understand the 12 classifications in the UL 94? What materials are they used for and how about their relative ratings? |

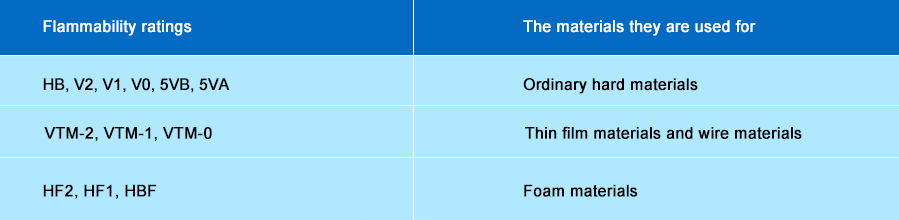

① UL 94 includes 12 flammability ratings:

② From HB to V to 5V classification, flammability test levels are from lowest to highest. The specimens must pass the low-level test before the next level test. For example, the specimen cannot pass the HB level test to directly perform classification V test or 5V test.

③ HB level test can be understood as: burning rate test + flame retardant qualitative test, HB level can also be called "flame-remiss level".

④ Conditions applicable to VTM flammability test:

a. Specimens of each thickness ≤ 0.025mm;

b. Specimens appear bending, shrinkage, floating, etc. during the V classification flammability test, so that the test cannot be completed;

c. Whether to do the V classification flammability test or VTM flammability test can be selected according to the material characteristic when thickness is in the range of 0.025-0.25mm. VTM-2, VTM-1, VTM-0 flammability rating can be analogously considered to correspond to V2, V1, V0 in the flammability classification of thin films.

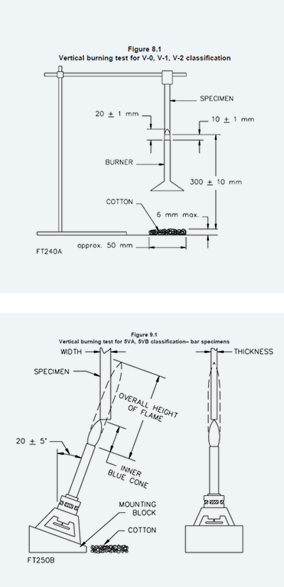

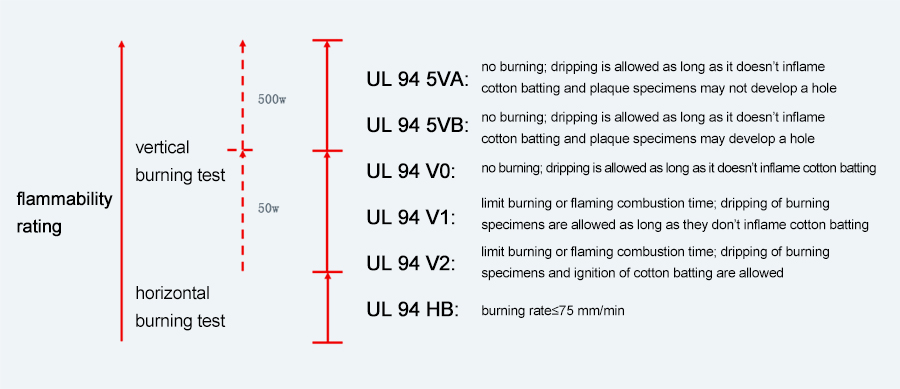

⑤ The flammability rating of ordinary hard plastics is summarized as follows; the definition of specific test methods and the evaluation of results are detailed in UL 94.

|

2. How to correctly describe the flammability rating of a material? |

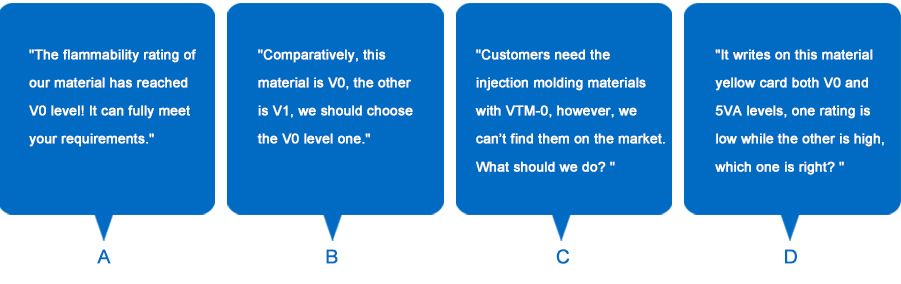

① Regarding to the flammability rating of a material, we may hear the following dialogues:

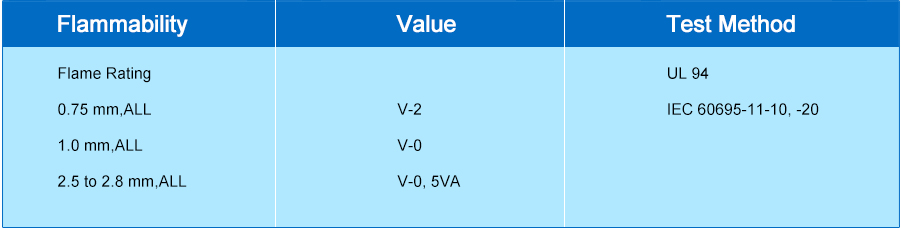

The flammability UL 94 rating is the most widely used flammability standard for plastic materials. Many values can be obtained from each material under test due to different color and thickness. The UL rating should be reported along with the material thickness and color, and reporting only the UL rating without thickness and color is not feasible.

Misunderstanding exits in the question of dialogue C, which can be found through the above analysis.

Generally speaking, the thinner the thickness of the specimens are, the easier they are to burn, and the lower the flame rating of the test is. We can find it from below flame-retardant test results of CHIMEI ABS (PA 764G).

Going back to dialogues A and B, we can find out the problems.

In summary, thickness is an important condition for flame rating; thickness data is required to be provided when inquiring or recommending a material.

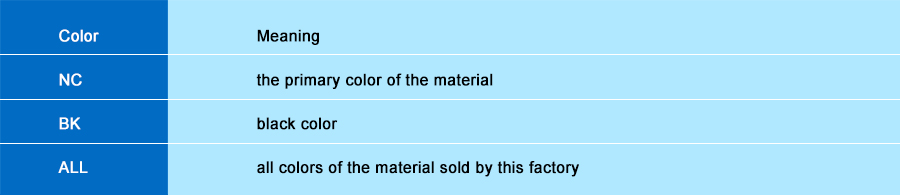

Regarding to colors, in general, the material supplier will only certify certain types of natural materials, and some relatively large material suppliers will perform UL flammability certification for all colors in this model.

When getting the yellow card for a material, we need to pay attention to the color column, which usually has three kinds of data:

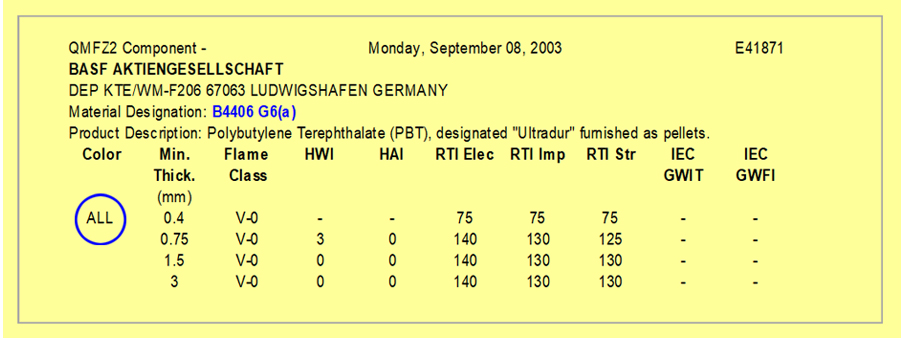

The following picture shows a BASF PBT+GF30 material, whose color column writes "ALL" , which means all colors of materials with this item number produced by this company are applicable to this UL yellow card.

When the color column of the yellow card is displayed as NC or BK, it is necessary to pay attention to whether the color of the final product is NC or BK. If the color needs to be adjusted, the test date on the yellow card does not necessarily represent the flammability performance of the product.

Relevant Recommendations:

Analysis of UL Flammability Standards II

UL is short for Underwriter Laboratories Inc. The UL Safety Laboratory is the most authoritative in United States and a very large private institution in the world for safety testing and identification.

INQUIRY

MOST POPULAR

- Analysis of UL Flammability Standards I

- RPWORLD Achieves ISO13485 Certification —Elevating Standards in Medical Device Manufacturing

- RPWORLD Further Improves Inspection Speed with New 3D Laser Scanning Machine

- RPWORLD Announces New Cafeteria Opening

- RPWORLD Enhances Precision Manufacturing with New 5-Axis CNC Machines

- Exciting Enhancements in Comprehensive Manufacturing Services at RPWORLD

23 March, 2020

23 March, 2020