A Small Hole,

the Great Capability

PROJECT BACKGROUND

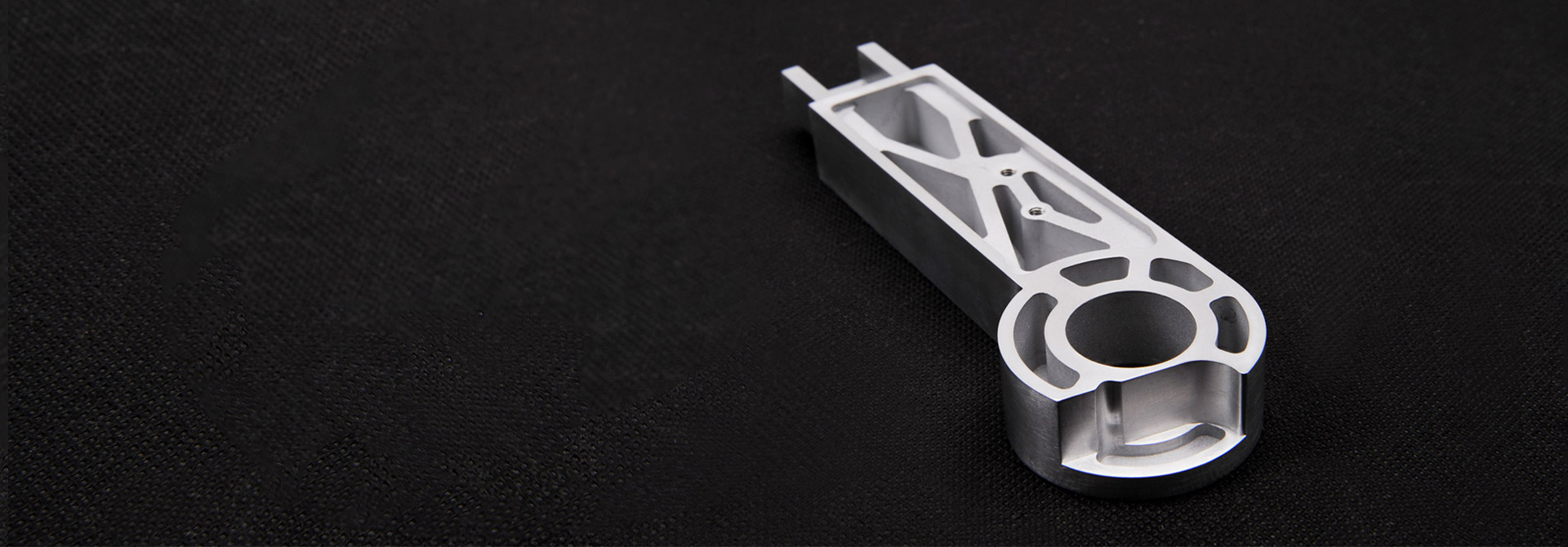

The client is a mechanical equipment company with more than 20 branches all over the world. They need prototypes matching their industrial installations. The prototypes are made of aluminum alloy, and high accuracy of holes are required. Different manufacturing processes and cutting tools will affect directly the precision standard of holes. The higher the accuracy of the hole, the stricter the requirements on the process and manufacturing machine. The client has contacted some low-volume manufacturing service providers. However, the manufacturing accuracy could not meet their requirement, so they asked RPWORLD for help.

CHALLENGES

★ The high accuracy of holes sets high standard on machining precision.

★ The lead time is short, as the client wants to get prototypes in two weeks.

★ The client expects higher quality parts with lower total cost.

With the thorough understanding of the project background, the engineering and production team realized that they must ensure the high precision of parts, and made a fast deliver under the premise of high-quality products. The most optimum solutions were made as following:

① CNC machining was the most suitable process after analyzing. The manufacturing precision of holes was affected by machines, cutting tools, and chip removal as well as heat dissipation conditions of hole manufacturing area. There is no doubt that 16-year experience CNC machining team are perfectly knowing the suitable process, cutting tool and machining operation to ensure the precision and quality.

② To meet the appearance requirements, the machinists polished the parts after CNC machining. The process will not extend the lead time, and make the parts look neat and great.

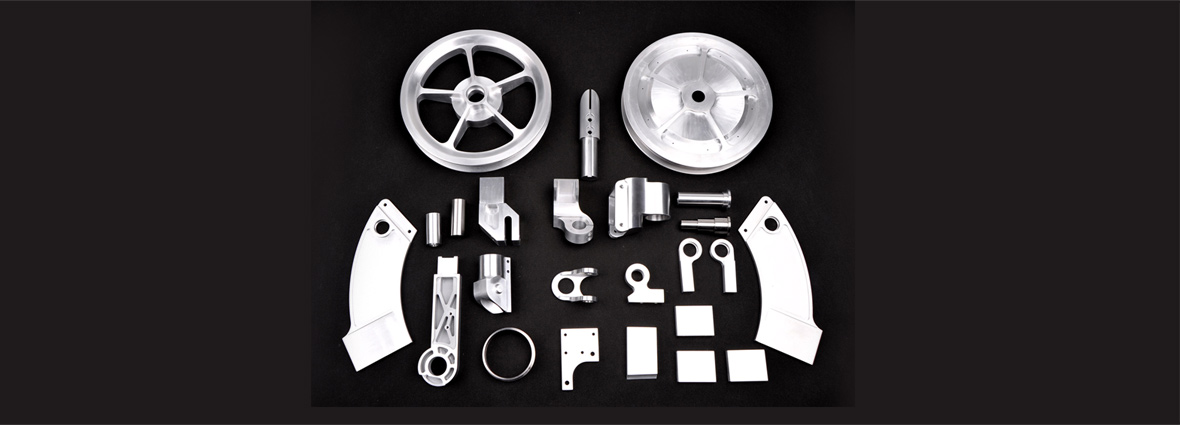

③ Applying 4-axis and 5-axis machines to production shorten 20% lead time. It took 10 days to turn CAD files to real prototypes.

CUSTOMER BENEFITS

1. Manufacturing the prototypes with high-accurate holes within 10 days accelerate the step for products to market, saving 20% development time.

2. The high quality and accuracy prototypes reduced 20% time and 30% cost of repeated communication and production.

TESTIMONIALS

By opening the package of my parts, I know RPWORLD doesn't let me down. It is well-known that the small holes in parts representing the great manufacturing capability. I have left you a task with difficulties, you have return me with products beyond my expectation. I really appreciate that, and please be prepared to my next projects.