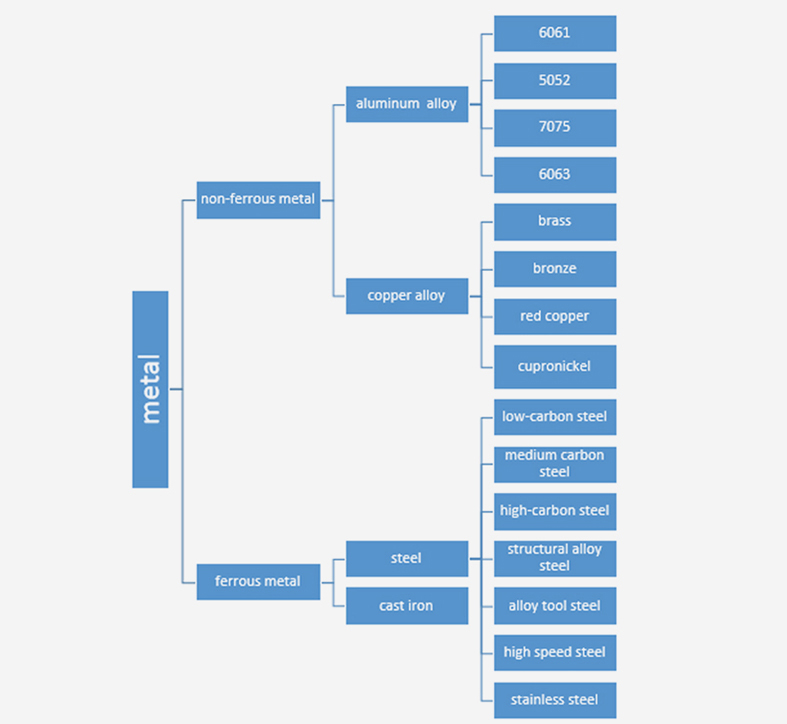

Cooper alloy:

consist of red copper, brass, cupronickel. Red copper is fine copper, mainly used as electrode for EMD(Electric Discharge Machining). Brass is copper and zinc alloy. It has good mechanical property, mainly used for conductive, heat conduction and corrosion resistant structural components. Bronze is copper-tin alloy. It has castability, anti-frication property and good mechanical property, mostly used for high strength and corrosion resistant components such as casting gear and sleeve.