How Does Bending Work?

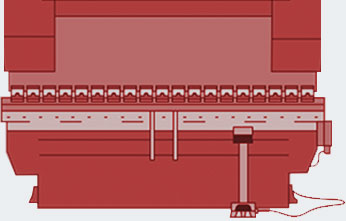

1. In a press brake, sheet metal is held in place by clamps between a matching punch and die, and the machine’s ram, with punch attached, moves downward to form a predetermined bend.

2. A folding machine relies on a swinging beam that folds the sheet metal, which is positioned and held by clamping beam tools.

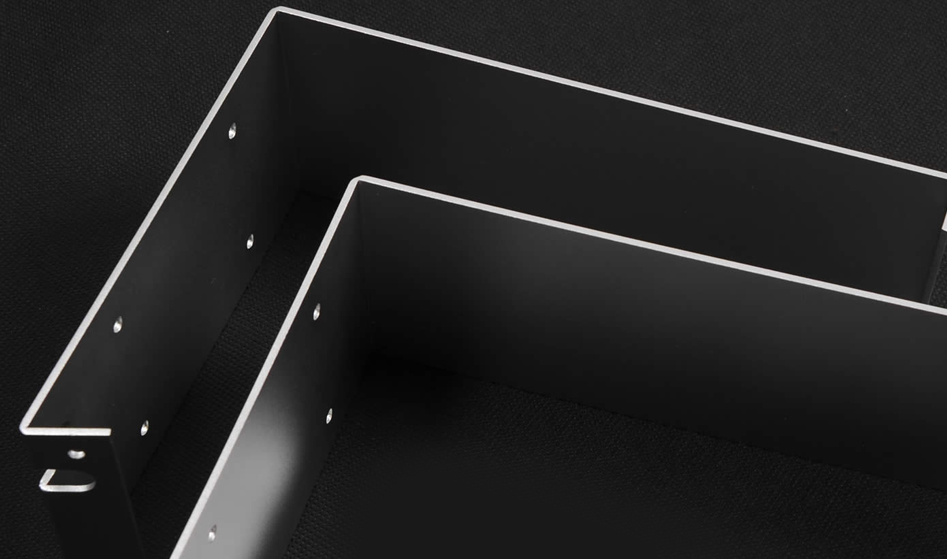

3. In sheet metal bending, the sheet metal is positioned below blank-holder tools, which descend and clamp it in place, with material protruding on the other side; the machine’s bending blades from above and below move to fold the metal.

4. Follow-up operations are often used to finish the sheet metal parts.