How Does SLA Work?

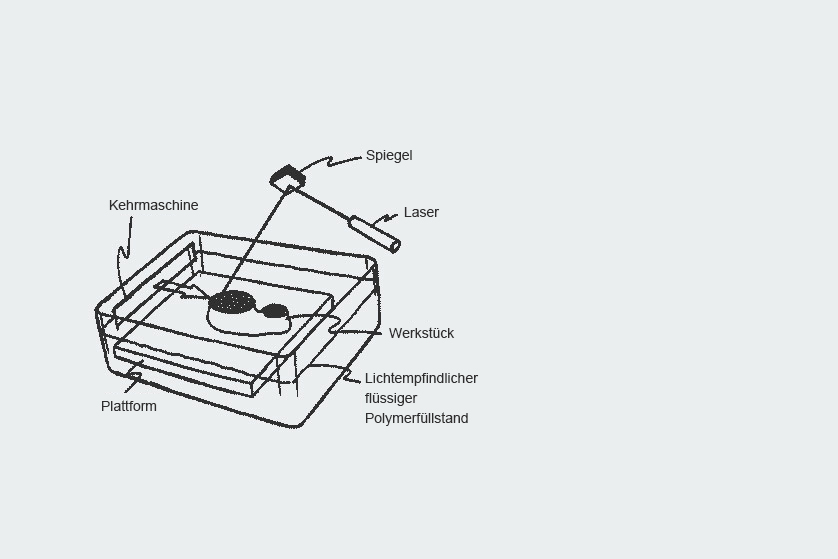

Firstly, the SLA machine starts to draw the support structures layer by layer. The part itself is followed with an ultraviolet laser aimed onto the surface of a liquid thermoset resin.

Secondly, when a layer is imaged on the resin surface, the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. The process is carried out layer by layer until the build is done.

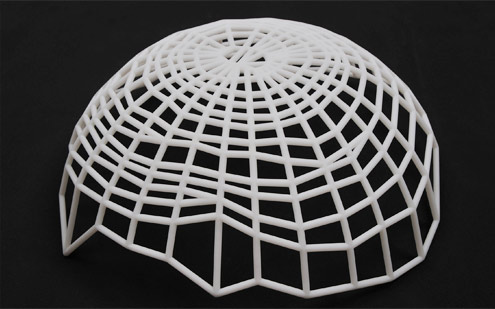

Thirdly, newly built parts are taken out of machine and additional resins are removed with solvents. When the parts are completely clean, the support structures will be removed manually. From there, parts will undergo a UV-curing cycle to fully dry and solidify the outer surface of the part.

Finally, the application of custom or customer-specified finishing will be implemented. Minimal UV and humidity exposure shall be applied on the parts so that they don’t degrade.