PROJECT

BACKGROUND

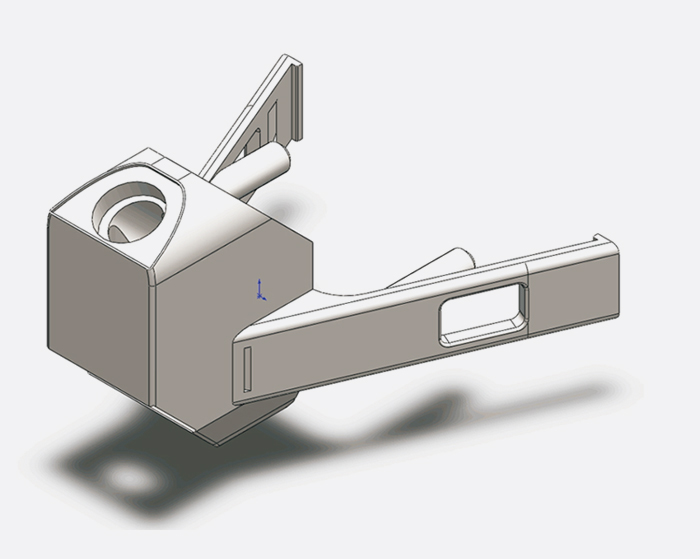

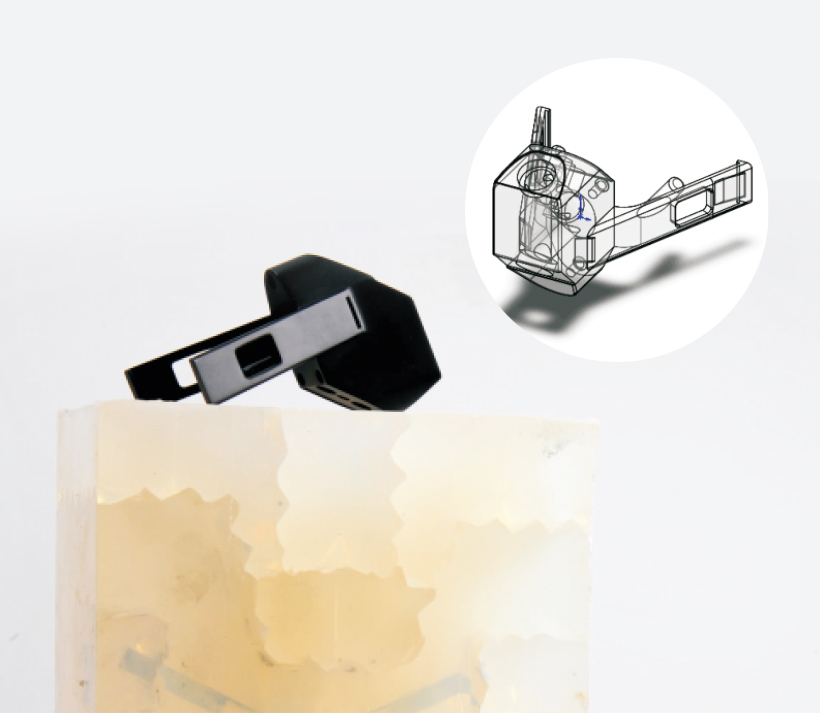

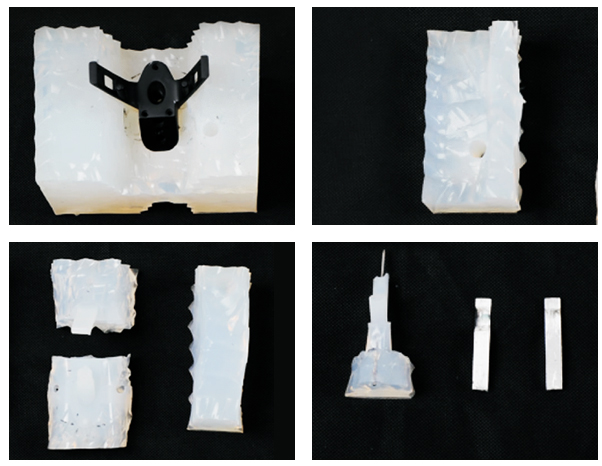

Our client, a high-tech company in the field of infrared detection technology research, appointed us for the production of 200 sets of optical probe components. Due to their complex structures and undercut details, injection molding or CNC machining were not feasible. Local suppliers in North America, were unable to do it unless the design was changed. However, to certify the product functionality, the structure design could not be changed. Thus the client turned to us for help.