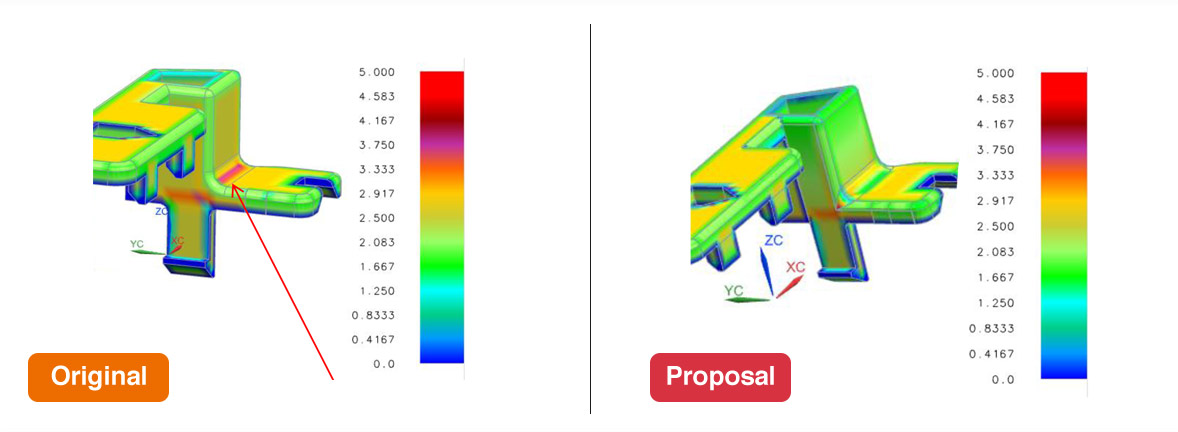

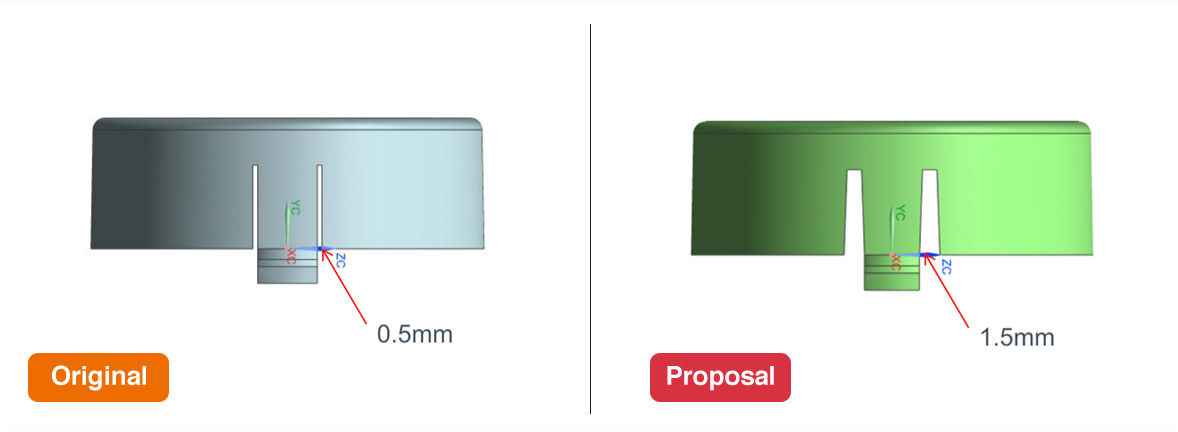

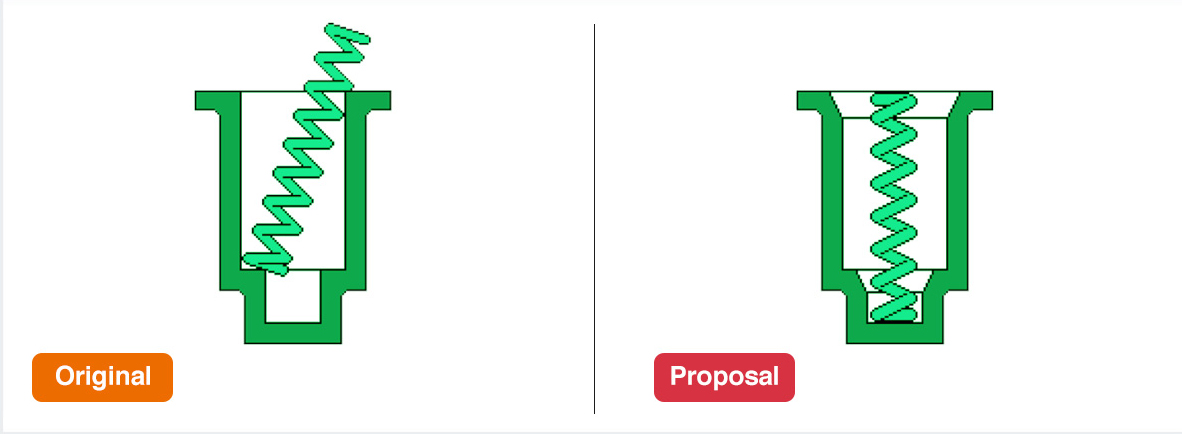

Manufacturability

Manufacturability refers to the ability of a part to be manufactured at a lower cost and higher quality. If the manufacturability of a part is high, then it means that the part meets the design requirements of the manufacturing process, it is easy to manufacture, the manufacturing efficiency is high, cost is low, defects are few, and quality is high.

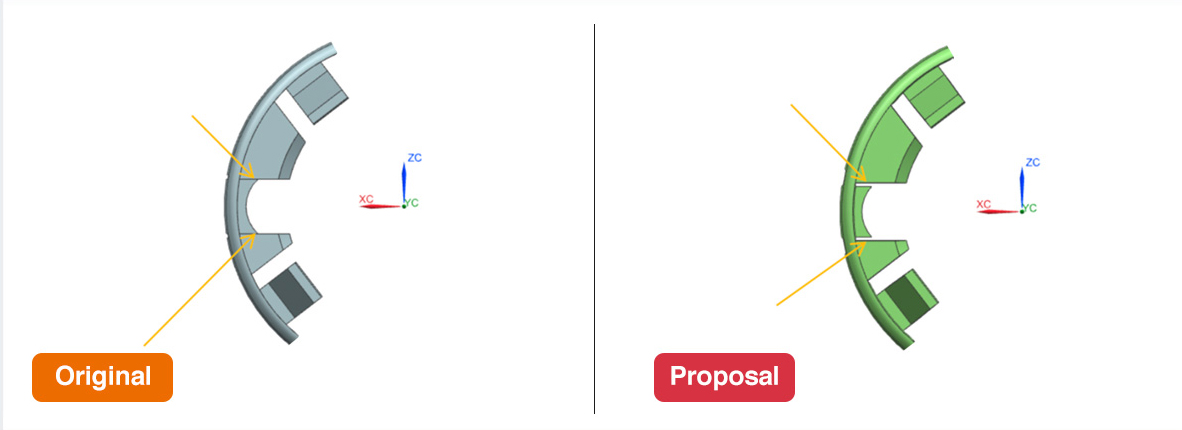

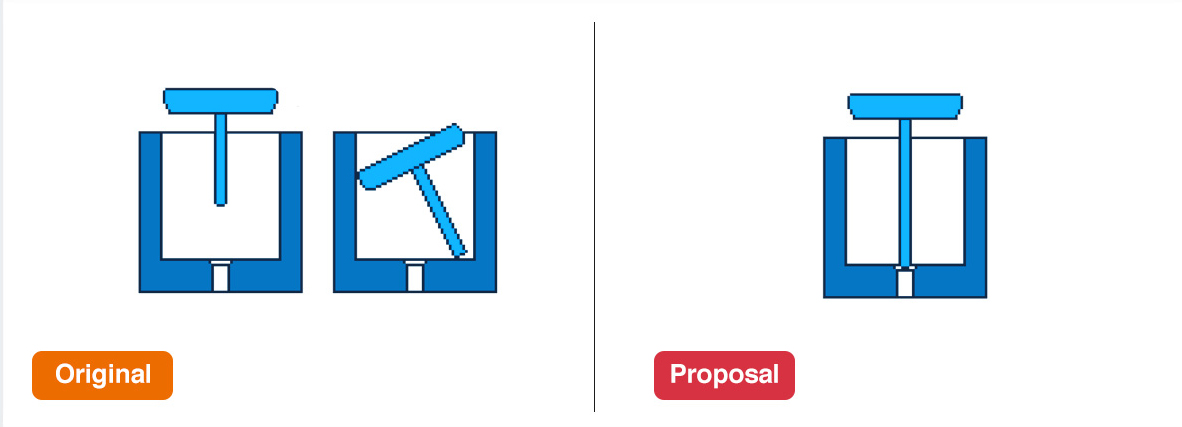

Assemblability

Assemblability refers to the ability of a product to be assembled at a lower cost and higher quality. The high assemblability of a product indicates that the design of the product satisfies the design requirements of the assembly process. The product is easy to assemble, has high assembly efficiency, low assembly failure rate and assembly cost, and high assembly quality.