CHALLENGES

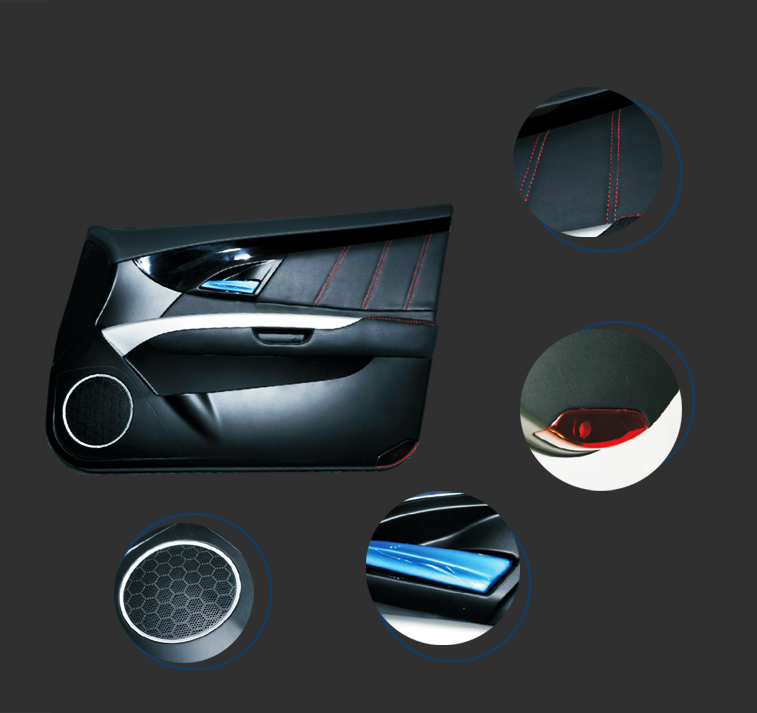

★ Full assembly parts delivery, complex color and texture solution

★ Leather covered surface

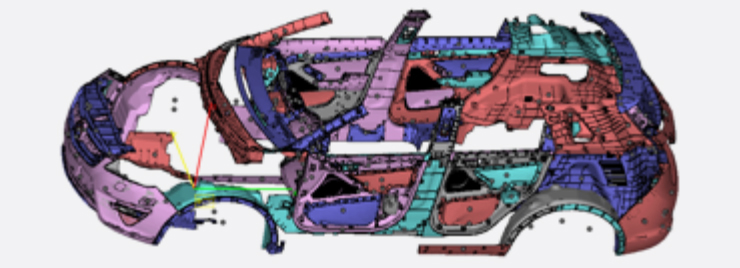

★ Details in accordance with the 3D files strictly

★ Assembly of electrical components

★ Functional tests

CUSTOMER BENEFITS

√ Lead time was reduced by 50%.

√ Production cost was 70% to 80% less than traditional tooling solution.

√ All production, after-treatment and pre-assembly was completed by a single supplier-RPWORLD, which greatly reduced project's technical risk .

√ Close communication and professional coordination ensured high quality and on-time product launch.

√ Long-term product development partnership with RPWORLD established.